Understanding Equipment Utilization and Availability Metrics

Key Highlights

In this article, you will learn:

- How to define equipment utilization and availability.

- Formula to accurately calculate utilization and availability.

- How to determine a machine's target hours of work.

I learned a lot about availability and utilization during my railroad construction days when I had the pleasure of working with a very big, very old and incredibly complicated tie tamper as a key production unit. You have not lived until you have worked with a machine like that. It took the full-time attendance of an operator, an oiler, and a mechanic. It vibrated itself to pieces at every opportunity and consumed wear parts at a rate that made Niagara look like a trickle.

What would you say if I told you that, over a two-year period, it had 100% availability and 100% utilization?

More on utilization and availability

- Utilization is the cornerstone of fleet management.

- Wasted equipment hours define work status.

- Renew the attack on unscheduled failures.

- Apply the Bradford Factor to equipment downtime.

It worked like this. Our contract made it clear that we would be permitted to take the tamper out onto the running track and use it for three—and only three—hours a day for the 360 working days in the year. Our owning cost rate was set knowing that we would need to recover all our fixed annual costs (depreciation, interest, insurance, tax, and the like) over no more than 1,080 hours per year (360 x 3), and our production targets were set on the basis that the machine would be available to work for 1,080 hours per year.

Our target was 1,080 hours per year. In other words, from an ownership cost point of view, we would recover the fixed annual costs and achieve 100% utilization if it worked 1,080 hours per year. From a production point of view, the tamper would achieve 100% availability if it was up, running, and able to support our construction operations for 1,080 hours per year.

The tamper worked when required, and both these numbers were achieved. Sure, both the estimated and the actual hourly owning cost rate was high, but this was due to the low number of planned or target hours the tamper was permitted to go on track and work. Sure, operating costs were high because a lot of technician time and a lot of downtime was needed to replace pumps, motors, and drive shafts; change out the wear parts; and perform preventive maintenance. But none of this occurred during the three hours per day when the machine was required to go on track and do its job.

Let’s take what we have learned about the tie tamper and define the following as measures for availability and utilization:

How to define utilization and availability

- Utilization = The time the machine is used divided by the time the machine is required to work and able to work.

- Availability = The time the machine is required to work and able to work divided by the time the machine is required to work.

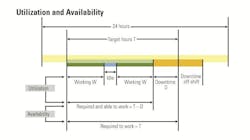

The diagram above shows how this works over a 24-hour period and gives the following formulas:

- Utilization = W / T-D

- Availability = T-D / T

- W = Operating hours or the time the machine works.

- T = The time the machine is required to work in a given period.

- D = The downtime experienced by the machine that prevents it from working when needed.

For our tie tamper, the value of T—1,080 hours per year—was clearly defined by the number of hours we were able to get on track and work.

Utilization was 100%, because the machine worked each and every minute of the three-hour working period allotted. There was no idle time in the three hours on track: It did not stand around waiting for instructions, work space, or other machines.

Availability was also 100%, because all the downtime (D) was off-shift. Yes, there was lots of downtime, but we worked long and hard when the machine was off-shift to ensure that no downtime was experienced when it was on-shift and required to work.

Time required for the equipment to work

It is clear that T, the time the machine is required to work, is the key number. Two things are important about T.

- It is the number you use to divide into the fixed annual owning costs when you calculate the hourly owning cost rate. This means that when you achieve 100% utilization, you recover 100% of your fixed annual owning cost and, when you get less, you will under-recover your fixed annual costs. We like the rates to be low, so we use the highest reasonable number and run the risk of under-recovering fixed costs. The tie tamper worked because we had a clearly defined target, we used it in our rate calculation, and we met it.

- If T, the target hours, is high then it is all but impossible to achieve high values for availability. If days are long, off-shift time is not available to do the inspection, maintenance, and repair work needed to keep machines up and running. There will be on-shift downtime. If you plan to work 14 10-hour shifts in a week, it is going to be extremely difficult to reach availabilities in the high 80s. The tie tamper achieved 100% not because it was a “good machine,” but because we had lots of off-shift time to prepare for faultless performance when it was required to go on track and do its job.

Four takeaways

- The formulas are simple. To make them work, it is critical that you have a well defined value for T, the target number of hours. Both utilization and availability are extremely dependent on target hours. It is impossible to acheive high values for utilization if days are long and if operations are not planned and executed efficiently. You cannot achieve high values for availability if you do not have or if you do not use off-shift time to ensure that equipment is good to go for the whole of the next shift.

- Availability is not about how “good” a machine is from a mechanical point of view. If you want to know that, you need other metrics. We used “down ratio,” defined as the number of hours down (regardless of when) for every operating hour and “repair factor,” defined as the number of technician hours spent on the machine divided by machine operating hours as key machine performance metrics. The tamper pulled a down ratio of about 1.7 hours down for every operating hour and a repair factor of a little over 2.2 technician hours per operating hour. In other words, we had a lot of downtime and used a lot of labor to deliver the availability that production demanded. The cost of on-track downtime was just too high: We had three hours per day to do the required job.

- Your owning cost rate depends on your target hours. Utilization is about fixed cost recovery. Achieve 100% utilization, and you achieve 100% fixed cost recovery.

- Availability is about the degree to which the machine supports production. Achieve 100% availability, and there is no downtime that impacts production. The machine is and able to work for every hour that it is required to work.

These performance metrics aren't about tie tampers and exotic machines like that. They are about everyday mixed fleets working on everyday jobs. Most companies expect equipment to work the same hours as their crews and set their target hours at 40 hours per week or 2,000 hours per year. It is an ambitious target, and you may have to lower this a little to avoid systematically under-recovering fixed costs.

If you set a standard and reasonably achievable value for target hours per year or per month, then you really simplify things a lot. Everything becomes a percentage of your standard value. Utilization at 90% means that it has been used for 90% of the standard value and that the fixed costs of ownership are slightly under-recovered. Availibility of 90% means that the machine has been able to support operations for 90% of the target hours in the year.

It is simple yet complex. As with most things, it is not how you do the arithmetic, it is how well you understand the numbers that drive the arithmetic.

About the Author

Mike Vorster

Mike Vorster is the David H. Burrows Professor Emeritus of Construction Engineering at Virginia Tech and is the author of “Construction Equipment Economics,” a handbook on the management of construction equipment fleets. Mike serves as a consultant in the area of fleet management and organizational development, and his column has been recognized for editorial excellence by the American Society of Business Publication Editors.

Read Mike’s asset management articles.