Excavator Production Heroes Take the Textbook To the Trench

It's too easy to settle for the usual way of digging trench when soil conditions or limited right of way challenge the textbook prescription for setting up a job. It's a mistake to throw out the textbook in less-than-ideal conditions, though, because even tiny improvements in production can add up to significant profit gains.

Consider this real-life example shared by a Construction Equipment reader. The contractor isolated the excavator cost in a 4,985-foot pipe-laying job. The estimate assumed a 76,000-pound machine would dig a foot of trench every minute and 41 seconds, at a cost of $2.26 per foot. A minor improvement in digging methods that trimmed just 5 seconds from each excavator cycle (a 5-percent change) would cut nearly a day from the project. More significantly, it would boost gross profit on the excavator portion of the job 33 percent higher than the estimate.

Almost anybody can improve their productivity by 5 percent. Programs such as Standards Based Operator Training (SBOT) from Caterpillar Equipment Training (CET) and VISTA Training's TIPS from the Pros videotape series recognize the value of refining experienced operators' skills. They focus on advice that will improve production with each cycle, but emphasize how to do it safely.

It's clear that any excavator operator should get OSHA's competent-person certification for trenching. The operator will be first to notice variations in soil conditions that require a change in trench shoring or sloping to keep people safe.

Before starting work on any site, the utilities need to be located and potholed to confirm their depth. VISTA's TIPS From the Pros series recommends walking the site to look for hazards like drop-offs, soft spots, and power lines. Climb down from the machine every now and then during the day to look at what's around behind.

Merle Hermsen, operator trainer at John Deere, pays particular attention to maintaining solid footing.

"Make sure the machine's setting level," he warns. "If you're working across a slope, bench up the downhill side so the trench walls will be straight up and down. If there's a hole behind you, swing around with a bucket full of dirt and level it off before you move back."

Everybody recommends inspecting a machine before starting to work. But Tom Brady, training coordinator for Cat's SBOT program, suggests that the best time for a really thorough once-over is probably at the end of the day. If you find a leak or a loose or broken part, there's a chance to fix the machine before the next morning. Grease will flow into warm joints much more easily, too. Then morning walk-arounds boil down to checking cold fluid levels and making sure the machine hasn't been damaged in the night.

When you're ready to start moving dirt (seat belt buckled, hydraulic fluid warmed up, gauges in the green) make sure excavators with work-mode choices are set at full power and boom priority. Approach the trench with the track idlers forward. Keeping the final drives behind you protects their bearings and seals from digging and lifting stress, and they provide extra counterweight.

Digging within the machine's power band makes maximum use of all that counterweight. The boom and stick are most powerful working in an arc that starts with the stick extended 35 to 45 degrees ahead of vertical and ends when the stick returns to vertical.

"It's typical for operators to work in one spot too long," says Brady. "They'll reach too far forward and pull back to within 2 feet of the tracks. It takes too long to fill the bucket.

"You never catch a break," he adds. "A steady stream of trucks really adds to the stress. Utilizing that power band will allow you to cycle faster, and it makes your life a lot easier."

In reasonable conditions, trenches should be dug from the top down, peeling material off in long layers just thick enough to fill the bucket by the time the stick is vertical. Start with the bucket floor at about a 45-degree angle to grade. The teeth will do the initial cutting by breaking the soil into pieces, but curl the bucket as the stick moves toward you. Use bucket breakout force to quickly penetrate to the desired depth of cut.

VISTA's new tape, "TIPS From the Pros: Excavators," points out that you will get a flatter trench bottom if you finish the cut with the bucket flat. Begin to boom up out of the trench before you curl the bucket, and only close it enough to retain the load. It saves time and helps avoid hooking utilities.

"It's easier to dig a level trench when you're slicing 6 inches deep and 8 feet long," says Hermsen. "You're almost practicing finish grading all the way down."

Don't use more finesse than you need, though.

"Know when to do precise work, and when to just bale dirt," urges the VISTA videotape narrator. "Don't waste time trying to make every pass a finishing pass."

Move dirt as quickly as is safely possible down to within 6 inches of the desired grade, or until the trench box should be pulled forward. At that point you may want to clean up spillage around the edge of the trench and pluck out any exposed rocks that might fall from the sidewalls. Then move the box into position and finish the trench.

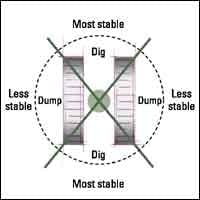

Try to pile spoil over a corner of the tracks, where swing time is minimized and the excavator is still quite stable. But spoil must be a safe distance from the trench (minimum of 2 feet, according to OSHA). Some jobs will be more profitable with an oversized excavator that can reach further without sacrificing productivity.

"If you're digging material that weighs 2,700 to 3,300 pounds per cubic yard with a 2-yard excavator," says Brady, "you have a few tons of material coming out of the bucket every cycle. You want that spoil as far away as you can get it and still be productive."

One way he recommends to get better distance without swinging farther is to dump through the spoil pile. He describes the motion as laying the bottom of the bucket on the pile and using it to push the pile away from the trench as you uncurl the bucket and stick out. You're moving the previous load back and replacing it with the load in the bucket.

Deere's Merle Hermsen recommends refining cycles by extending the stick only about 40 degrees when dumping the bucket.

"It leaves the arm in position to start digging when you come back to trench," he says.

Great time savings can be gained in truck placement when you're loading spoil to be hauled away. In the rare textbook example, off-road haul units back up close to the trench and the excavator swings less than 45 degrees through their open end gates to dump.

Loading over the end gate requires the least amount of booming up to put the bucket over the truck, and allows you to dump while swinging over the length of the bed. You don't have to stop swinging to dump over a narrow target, which is what happens when loading over the truck's side rails. Hitting the target is easier on the machine, too, because the swing brake doesn't have to stop 3 tons of material.

Of course, most construction jobs use highway trucks with tailgates to haul spoil. But the tailgate of an on-highway truck is lower than its sideboards, so you still save some booming-up time working over the rear. And there's serious motivation to dump while swinging the length of the truck because the dump body is generally narrower than an off-road hauler's. Loading a highway truck over the side rails presents a small target.

"Any time you can dump while you're swinging, you will reduce cycle times 6 to 9 percent compared to loading over the side," says Brady. "The best arrangement on a construction site is usually to have the truck beside you, where you can swing 90 degrees and be over the tailgate.

"If you have to swing more than 90 degrees, switch the machine over to swing-priority mode," Brady adds. "You'll swing faster, and still have plenty of time to get the boom up over the truck bed. But remember: If you're not blending three functions, you get no benefit from work modes. The machine is designed to work most efficiently when you're using three functions at once."

When limited right-of-way forces trucks to back in behind the excavator, you must blend functions to get the bucket ready to dump and dig while swinging. It's one of the only time savers available.

Limited right-of-way seldom offers the opportunity to slip trucks in at an advantageous angle, but watch for it. Any time you can load over the tailgates you'll be a hero.

Safe improvements in production are within everybody's grasp, especially with programs like Cat's SBOT, other manufacturers' training efforts, and third parties such as VISTA's TIPS from the Pros. In light of today's razor-thin margins, a little productivity can earn big profitability.

"One point we make when we train operators is that all of the profit for a day on most jobs is made in half an hour," says Rich Deeds, fleet manager at Brubacher Excavating, an eastern-Pennsylvania firm with about $30 million worth of equipment in the field. "If they're unproductive for half an hour, the job loses money for the day. But if they can find a way to improve productivity just a little, they can easily double the profit."

For more information about operator training from the sources in this story contact:

Caterpillar - (800) 962-6628

www.cat.com/services

John Deere - Bob Miller

VISTA Training - (800) 942-2886

About the Author

Larry Stewart

Larry Stewart was on the editorial staff from 1989 to 2010. His work won numerous editorial awards.