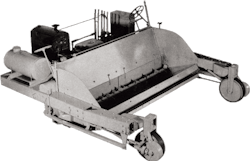

Adnun Asphalt Spreader

Mechanized asphalt paving originally used the same kind of technology as concrete paving of the time: A spreader or screed distributed and smoothed the material as it rode on forms that contained and shaped its edges.

In 1932, The Foote Co. of Nunda, New York, introduced the first free-traveling asphalt spreader, the Adnun (Nunda spelled backward) Paver, offered through its Adnun Engineering and Manufacturing Co. subsidiary.

The Adnun’s front frame extended forward on each side of the dump truck that was charging it, and each arm of the frame ended with a single wheel on which a solid rubber tire was mounted. A hopper between the arms and against the frame received the asphalt, but the truck had to use spreader chains to keep the tailgate from opening completely and flooding the hopper. The back of the paver travelled on roller drums, one on each side, that rode on the freshly laid pavement; the drums were also power driven, but could not exert much driving force as they would spin out on the fresh asphalt. Any soft grade or loose base rock would cause big problems, as neither the solid rubber tires nor the drums actually provided much traction. It worked better on a tight, hard surface, but even so a chain and cable were laid from the paver to a hitch on the truck’s front bumper, so that the truck helped propel the paver.

Depth of material was determined by a reciprocating cutter bar that spread and struck material off at the back of the bottomless hopper. The cutter bar bore more than a slight resemblance to the cutter bar of a sickle-bar mower. Care had to be taken to not dump more material than the machine and truck combined could move, nor to dump too little, as the only way to augment low spots or voids was with a shovel and rake. In 1933 or 1934, the single drive rollers were replaced by dual rollers. This eased the problem of the single rollers shearing into the mat due to the load-bearing capacity of the mat being exceeded by the weight of the paver and material in the hopper. A spinning agitator/raker bar was placed at the bottom of the hopper to distribute the material to the cutter bar.

Veteran operator Ernie Copp described the Adnun as “pathetically inadequate except under perfect circumstances” and “a nightmare to work with.” But, according to Copp, the few surviving Adnuns found a new life in southern California in the 1950s. A housing boom created a shortage of hot mix asphalt, so water-bound Macadam became a popular choice for subdivision paving. “It was absolutely terrible trying to lay that large stone to grade with a grader, as the cutting edge would continually flip up the stone,” Copp said.

Slightly better results were obtained by backblading the stone after it had been roughed in going forward. After someone had the idea to try an Adnun instead, it turned out to be the perfect machine for the task until the hot mix shortage was remedied.

The Historical Construction Equipment Association (HCEA) is a 501(c)3 non-profit organization dedicated to preserving the history of the construction, dredging and surface mining equipment industries. With over 3,800 members in 25 countries, our activities include publication of a quarterly educational magazine, Equipment Echoes, from which this article is adapted; operation of National Construction Equipment Museum and archives in Bowling Green, Ohio; and hosting an annual working exhibition of restored construction equipment. Our next International Convention and Old Equipment Exhibition will be August 27-29, 2021, near Concordia, Kansas. Individual annual memberships are $35 within the U.S. We seek to develop relationships in the equipment manufacturing industry, and we offer a college scholarship for engineering and construction management students. Information is available at www.hcea.net, by calling 419.352.5616, or emailing [email protected].