Volvo Units Provide Covid-19 PPE

Businesses across Volvo Group’s North American footprint are providing personal protective gear for U.S. healthcare professionals.

Volvo Penta is manufacturing personal protective gear in two of its U.S. facilities, and distributing them to local healthcare workers.

In Chesapeake, Virginia, engineers used a selective laser sintering 3D printing system and mask components from other Volvo Group business areas to deliver face shields to Chesapeake Regional Healthcare. It plans to produce more shields for distribution elsewhere.

In Germantown, Wisconsin, the engineering office has developed ear guards that to help alleviate pain from wearing face masks. More than 1,000 have been shipped to hospitals, rehabilitation centers, nursing home, and pharmacies, according to the company, located in seven states: Colorado, Illinois, Iowa, Florida, Michigan, Nevada, and Wisconsin.

“Together with our colleagues from Volvo Group North America, we are honored to support relief efforts and help protect those serving on the front lines of this pandemic,” said president Martin Bjuve in a prepared statement.

Volvo Penta also made a charitable donation to the Foodbank of Southeastern Virginia and Eastern Shore to support those in the Hampton Roads community where the organization is based.

In Shippensburg, Pennsylvania, headquarters of Volvo Construction Equipment, a cross-functional group delivered 1,600 face shields and ear guards to local healthcare providers and first responders in Shippensburg, Chambersburg, Carlisle, and the surrounding region.

The face shield is now one of the most in-demand pieces of equipment, according to Volvo CE. It is used as a second barrier to cover and protect the N95 respirator mask and extend the mask’s life. The shield lenses are sourced from an internal supply of replacement lenses, normally stocked for fabrication grinding, and attached to 3D-printed visor brackets to make a functional equivalent to the medical-grade face shields used in hospitals. Foam rolls, sourced from the cab assembly line, are cut and used to pad the shield visors, as well as shipped to fellow Volvo Group sites to support their face shield production activities.

Said Brian Rudge, team leader for Volvo CE, in a statement:

“At Volvo CE, we have a ton of talent, resources and capability that we can deploy to help in the fight against the virus. It is who we are; our people care for the community. They are problem solvers. And they are talented, engaged and determined to make a difference.”

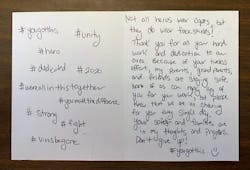

Additional Volvo CE employees are writing personal notes (right) of encouragement that are added to the delivery boxes. The site is also collecting bleach and disinfectants for local EMS departments, which are consuming supplies at a rapid rate, due to rigorous cleaning requirements.

The Shippensburg task force has connected WellSpan Chambersburg Hospital with potential vendors to supply it with 100,000 surgical masks, another standard device now in short supply.

“It is no longer ‘business as usual’ for Volvo CE or for our healthcare community,” said Tony Zambito, road director for Volvo CE, in a statement. “This grass-roots effort shows how our industry is able to make an impact in unprecedented ways and demonstrates the character of our employees.”

The company said tens of thousands of PPE units are being donated from Volvo Group North America sites in Pennsylvania, Maryland, North Carolina and Virginia, in the U.S., and Quebec, in Canada.

Source: Volvo Penta & Volvo Construction Equipment