Telematics Reveals Equipment Usage During Covid-19

An index created by telematics provider Trackunit is monitoring the effects of unplanned downtime on equipment due to the Covid-19 pandemic.

Called the "Downtime Index," the data illustrates the weekly changes in engine usage among around 150,000 off-highway construction machines in Europe and North America. Some 40 percent of the data comes from the U.S., Denmark, Germany, and France. The virus has hit three out of those four countries particularly hard.

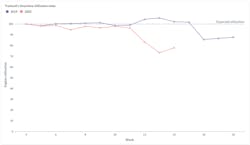

The graph at the top of the page depicts the Downtime Index, identifying a large change in utilization following week 11. By week 14, however, there is a 6 percent increase in the Index, meaning that after two weeks of gradual decline, machines are now being used more.

Fewer machines doing more: telematics

The caveat is that the utilization is still 22 percent below what Trackunit would have expected, and 25 percent below the utilization experienced in 2019. Interestingly, looking at the machine activity, there is a 2 percent fall from week 13, indicating that fewer machines are being used more frequently at the construction sites.

Join the Equipment Managers Confidence Index.

This is expected since some machines are easier to shut down and more versatile machines are being used more and for wider tasks. Fleets may be keeping the most versatile performers and right-sizing as an adjustment to the challenging economic conditions.

What happens to fleets after Covid-19?

Trackunit has some suggestions on what fleets can do during the pandemic to overcome the inherent challenges and position them well for an economic rebound.

One is putting machines into a better state.

Most OEMs’ spare part activities are still ongoing across North America and Europe, Trackunit points out. Major rentals also provide service on their machines. Contractors are working on job sites with less and less machines, according to the Index. Service technicians’ availability is significantly increased. These factors provide an opportunity to focus on general health of machines that are standing still.

Protecting the safety and health of service technicians should remain first priority for all of construction. However, when equipped with appropriate safety clothing, technicians can focus their efforts on general service schedules and preventative maintenance of machines.

Parked machines during such crisis times make it possible to investigate and fix root causes thoroughly. This will provide long-term benefits across the construction value chain when economy rebounds and job sites are filled with more healthy machines and operators.

How the telematics-powered Index works

The Downtime Index compiles weekly harmonized engine utilization changes. Engine utilization is defined as voltage activity on a machine’s alternator. Trackunit expresses the changes as index numbers to allow for quick international comparisons. The index starts at week 4, which is referred to as the base week.

In subsequent weeks, percentage increases push the index number above 100, and percentage decreases push the figure below 100. An index number of 102 means a 2 percent rise from the base week, and an index number of 98 means a 2 percent fall. The underlying data comes from a fully anonymized cohort of approximately 150,000 off-highway construction machines in Europe and North America.

The Index is part of an overall campaign by the company that is themed #eliminatedowntime.

Source: Trackunit