In the 1930s, the Wagner family of concrete contractors in Portland, Oregon, began working on means to more efficiently produce and place concrete for small projects. The initial result was the distinctive machine that gave its name to what became their equipment business, Mixermobile Manufacturers.

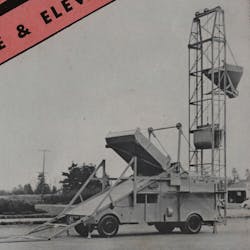

The Mixermobile carried a concrete mixer and charging equipment, plus an optional elevating tower, on a rakish-looking truck chassis. The angled front of the truck mounted the track for the tray-like charging skip, which was loaded on the ground then winched up and over the cab to dump into the mixer. Concrete discharged from the rear.

With the tower in place, it went into a storage hopper equal to the mixer’s capacity and half the capacity of the bucket inside the tower; thus, it placed two buckets of concrete as each new batch was mixed. Towers to 55 feet high without guying were available, and everything folded down for roading. It’s worth noting that the Wagners developed the Scoopmobile, one of the first true wheel loaders, originally to charge the Mixermobile’s skip in confined areas such as city streets.

To enable placement of concrete away from the tower, the Wagners also came up with the Buggymobile. Built on the three-wheeled chassis of their model B Scoopmobile, it sported a hopper on a short forklift-like hydraulic mast. Two models were offered, a half-yard hopper that could discharge as high as 3-1/2 feet above surface, and a one-yarder with 6 inches more discharge height. Weighing only 2,700 or 4,300 pounds, respectfully, they could be lifted by crane to elevated working areas. Like the B, it steered by means of a tiller-like handle that dangled in front of the operator. A mast-and-hopper arrangement was also offered for at least one model from their pioneering articulated wheel loader line.

Rounding out the line were the Towermobile and Towermobile Crane. The Towermobile was essentially a Mixermobile without the mixer. Instead of a skip, a hopper to receive concrete was winched up and over to the storage hopper in back. The Towermobile Crane mounted only the tower, and/or a simple 20-foot boom that could be extended to 40 feet on a slightly more conventional factory carrier. The boom was roughly over the rear axle, and the tower mounted to the back of the truck’s frame. The boom was intended only for lifts and clamshell work, and its capacity is unknown.

About the HCEA

The Historical Construction Equipment Association (HCEA) is a 501(c)3 nonprofit organization dedicated to preserving the history of the construction, dredging and surface mining equipment industries. With over 3,500 members in a dozen countries, our activities include operation of National Construction Equipment Museum and archives in Bowling Green, Ohio; publication of a quarterly magazine, Equipment Echoes, from which this text is adapted, and hosting an annual working exhibition of restored construction equipment. Individual annual memberships are $45 within the U.S. and $65 elsewhere.

Our next International Convention and Old Equipment Exposition will be held August 28-30, 2026 at Concordia, Kansas. We seek to develop relationships in the equipment manufacturing industry, and we offer a college scholarship for engineering students. Information is available at www.hcea.net, or by calling 419.352.5616 or e-mailing [email protected].

About the Author

Tom Berry

Tom Berry is archivist for the Historical Construction Equipment Association (HCEA). Information is available at www.hcea. net, or by calling 419.352.5616 or e-mailing [email protected].