How to Build a Training Matrix for an Equipment Shop

Key Highlights

In this article, you will learn:

- How to use a training matrix to map roles to required skills.

- How to ensure workers have necessary training.

- How timelines and costs enables better scheduling and budgeting.

As headcount grows in the maintenance shop, so does the complexity of the little details. One of the biggest headaches for any shop or fleet manager is keeping track of who has what training and why they need it.

Every manager has been there. A mechanic is sent to a site only to be turned away because their orientation wasn’t completed. A service truck needs to be dispatched, and the only available mechanic doesn’t have a commercial driver’s license. Or a new hire arrives on the job without the certifications that were assumed to be a basic requirement for the role. These moments waste time, drain budgets, and hurt credibility.

Situations like this happen every day, and one tool can help to prevent them: a training matrix.

What is a training matrix?

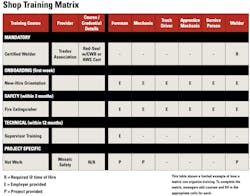

At its core, a training matrix is a table or a spreadsheet, but its value goes beyond rows and columns: It shows who works in the shop, what skills are needed, and how they’re gained. Think of it like a map: Across the top are the positions that need to be managed, down the side are the trainings, and in the middle is the plan that connects the two. Every role has its own column—foreman, mechanic, truck driver—making it easy to see at a glance what’s required for each position.

The result is a single, clear reference point for all training by position. It identifies what must be in place at hire, what the company will deliver after onboarding, and what is handled by site teams at the project level.

How to make a training matrix

Building a training matrix starts with two simple lists: all the roles in the shop and all the training that could apply to those roles.

Start with the columns. In the first column of the example table nearby, list the training course. In the next two columns, list the course details—where it’s delivered (in-house or off site), who provides it, and what credential or course. Adding details makes the table clear, and links to courses and credentials makes it a useful reference.

Next, organize the list of trainings into groups that make sense for the business. In the our example, headers indicate those groupings:

- Mandatory, the baseline certifications needed to be hired, a welder’s certification, for example.

- Onboarding, the courses every new hire must complete right away, such as company orientation.

- Safety, training that applies across the shop and field, such as fire extinguisher.

- Technical, skill training unique to certain roles, for example, foremen need supervisor training.

- Project-specific, site-driven requirements such as hot work. These aren’t optional: Workers can’t step on site or perform work without them.

Once the training is grouped, add the roles across the top row, in our example, the last six columns. Each role has its own column, making it easy to scan and see exactly what training applies to that position.

The final step is to fill in the grid beneath the roles. That’s where the legend comes in. The coding system is what makes the training matrix work. Instead of long notes, a single letter in each cell tells the story.

- R = Required. These are baseline certifications or licenses that must be held before hire.

- E = Employer-provided. This is training delivered by the company, either in-house or through a vendor.

- P = Project-provided. This is training delivered by the project site.

This approach also keeps the table clean and visual. At a glance, anyone can tell what’s needed, who provides, and where the responsibility sits.

A training matrix may look like a simple table, but the impact is significant. It removes the guesswork from workforce planning and ensures that no one slips through the cracks.

From a hiring perspective, the matrix defines what must already be in place at the time of hire. HR and recruiters can see that mechanics need a journeyman ticket, truck drivers need a CDL, and welders need a welding certification. This prevents surprises after hiring someone.

From an operational standpoint, it saves time and keeps projects moving. Dispatching a worker without the required training leads to delays, wasted mobilizations, and frustrated operations managers. With a matrix in place, managers know immediately what positions are qualified for what work.

It also strengthens compliance. When project owners, auditors, or regulators ask for proof of training, the company has a clear standard showing requirements by position. This reduces risk and builds credibility.

A real life example

Here’s how the training matrix works in practice.

Take a welder, shown in the far right column. The Certified Welder ticket is marked R, a requirement before hire. Once hired, the welder also completes core courses like orientation and safety training such as fire extinguisher (E). If assigned to a Mosaic project, the welder would need to complete Hot Work training (P) at the site.

By reading across rows and down columns, managers can see the whole training story: what’s mandatory, what’s the company’s responsibility, and what’s handled at the project level.

How to level-up

A basic training matrix is a powerful tool on its own, but it can also be taken further. Not every employer-provided training is required for Day 1. Adding timelines—such as “first week,” “within 3 months,” or “within 12 months”—helps coordinate when each course needs to happen. That way, trainings can be scheduled with confidence.

Another enhancement is adding costs and durations for each course. For example, forklift certification may cost $300 and last three years, while supervisor training may cost $1,200 and last indefinitely. This transforms the matrix into both a training plan and a budgeting tool, giving managers a clear picture of the investment required for each new hire.

Finally, many companies are now integrating their training matrix into a Learning Management System (LMS). These systems handle expiry tracking automatically, send reminders, monitor completions, and generate reports for audits or client requests, turning a static spreadsheet into a live management tool.

A training matrix is one of the most effective tools for managing a shop. Just as equipment can’t leave the yard without being fueled and inspected, workers shouldn’t leave without the right training. A training matrix helps to ensure the workforce is prepared, competent, and ready for the job.

About the Author

Craig Gramlich

Craig has extensive experience in equipment management across transportation, heavy lifting, civil projects, mining, and construction sectors. Driven by a passion for cost and data analysis, he excels in enhancing equipment accounting, rate modeling, and developing programs for rate escalation and transfer pricing.

Through Lonewolf Consulting, Craig effectively unites Equipment, Operations, and Accounting departments, leveraging his extensive field experience to help companies streamline operations and find cost savings, significantly boosting ROI.

He holds a Bachelor of Commerce from the University of Alberta and a Certified Equipment Manager (CEM) certification, along with a variety of professional development courses, showcasing his commitment to ongoing professional growth.