Automatic Lubrication: Where Time, Grease, and Downtime Collide

Key Highlights

In this article, you will learn:

- Downsides to manual lubrication.

- How automated lube systems work.

- How specialized grease adds benefits.

- ROI on automated lube systems.

Every contractor running a cold milling machine knows the grind isn’t just under the cutter drum. A Wirtgen W-220 XFi milling machine has 63 grease points, and each one needs to be hit with various frequencies and volumes, some daily, others weekly, as so forth. Miss a friction point and you don’t just shorten bearing life, you risk seizing components that can shut down a big-ticket machine mid-job.

Published with permission from Lubrication Technologies.

A contractor in northern Maine, who works through one of the shortest paving seasons in the country, saw maintenance taking a chunk out of its workdays. Crews spent half an hour every morning on necessary lubrication, struggling around awkward fitting locations and burning through tubes of grease. Cleanup was constant. Over-greasing created needless waste that had to be cleaned, under-greasing left components dry, and the whole process did not provide the desired results.

Manual lubrication has two built-in flaws. First, it relies on human memory and consistency, which falters under job site pressure. Second, it delivers grease in uneven bursts. Bearings need small, metered volumes delivered regularly so the film is ever present.

Why switch to automated lubrication

The Maine crew partnered with their equipment dealer, who selected Lubrication Technologies to install a ReliaMAX system built around an 8-kilogam electric pump and divider valves mapped precisely to each of the 63 points. Progressive divider valves provide precise delivery of lubricant through the sequential operation of spool valves in measured volumes. They guarantee each point receives the right amount.

Hose runs were routed to avoid high-vibration zones and debris pinch points. A digital controller regulates delivery times and alerts personnel via both an audible as well as visual alarm when either a low-level or no flow condition exists. A manual override is available for system operation confirmation and/or diagnosis in the event of an issue.

What set this install apart was not only the hardware, but also the grease selection. The system utilizes Lubrication Engineers’ Almagard Vari-Purpose Grease. This heavy-duty lubricant contains tackifier additives that keep the grease anchored to metal under shock loads yet provide excellent pumpability in the conditions the machine will operate. The base oil/additive formulation resists shearing down under vibration, and the red dye provides a visual check for coverage. Crews who had seen standard grease fling off couplings within hours found Almagard still in place at the end of a shift.

The ROI on automated lubrication

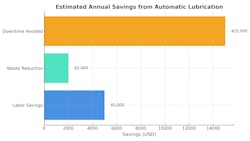

Roughly 125 hours per paving season were recovered by automating grease, according to estimates, which translates into about $5,000 in labor cost. Precision delivery eliminated the mess of over-application, cutting another $2,000. Finally, a W-220 sitting cold for a day can cost tens of thousands when you factor idle operators, penalty clauses, and rescheduled trucking. Preventing even one lubrication-related breakdown pays for the system outright.

Most crews see auto-lube as a labor saver, but that’s the smallest part of the payoff. The real gain is the extension of equipment life and uptime stability. Automatic systems meter grease in ways humans never can. Pair that precision with a grease formulated to resist shock loads, vibration, and high levels of contamination, and you control the single biggest hidden cost in milling, lost production hours.