CX330 Advances Case's Excavator Technology

| Test Set | |

| New model | CX330 |

| Type | Excavator |

| Replaces | 9050B |

| Available | Mid 2002 |

When Construction Equipment editors worked with Case to evaluate the company's new CX330 hydraulic excavator against the model it replaces, the 9050B, our trenching comparison had the machines digging down to 12-plus feet in stubborn, brick-hard clay that seemed ready to pull them in with every bucket load. The site, a borrow pit for landfill cover in North Cape (near Racine), Wis., is owned by A.W. Oakes & Sons, a local earthmoving firm. The company's Dan Oakes was gracious enough to allow us to use the site, and also loaned us one of his best operators, Brian Torgerson, who worked with Case's Russ Wadzinski during the field-test evaluation.

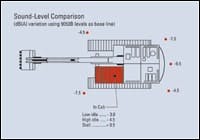

And when trenching in this obstinate material, the new 30-metric-ton-class CX330 bested the productivity of its predecessor by nearly 10 percent, while exhibiting quite a notable fuel-efficiency advantage. Our comparative tests also included over-the-front lifting, swing acceleration and an evaluation of sound levels. As you'll see from the results, the CX330 represents quite a big technical step forward from its popular, though less refined, predecessor.

We conducted the evaluation on two particularly warm Wisconsin days in mid-September. The CX330 was virtually new, from the Case demo fleet, and the 9050B was a low-hour rental unit. Both were equipped with identical digging arms (13 feet 3 inches), both used 2.19-cubic-yard, 48-inch-wide buckets with side cutters, and both were fitted with 32-inch track shoes.

Representing Case at the test were marketing manager Dave Wolf, product manager Bob Weiglein, chief engineer Bob Tuszka, and Joe Hanneman, Case's public-relations manager from Malcolm Marketing Communications.

The Case 9050B, with a standard operating weight of around 73,500 pounds, has been a solid performer in the company's B-Series excavator line since its 1994 introduction. For the past two years, however, Case has been replacing its B-Series machines with CX-Series models, which now number eight, ranging from 7 to 80 metric tons. CX-Series machines, compared to their B-Series counterparts, says Case's Dave Wolf, have been essentially redesigned from the tracks up.

The new models, jointly developed by Case and Sumitomo Construction Machinery, are manufactured in Chiba, Japan. Case, however, supplies the Chiba factory with a number of key components, including Case engines (made at the Case/Cummins factory in Rocky Mount, N.C.), viscous fan drives and cooling-system components.

The CX330, in standard trim, is some 4,500 pounds heavier than the 9050B. The added weight comes primarily from a larger counterweight and from a redesigned carbody that now entirely encloses the swing system. These added pounds contribute to the boost in the new model's over-front lift capacity and, in combination with higher hydraulic pressures in the travel circuit, give the CX330 an impressive 16-percent boost in drawbar pull, which means more power for negotiating poor underfoot conditions and steep grades.

In addition, the design of the CX330's digging linkage has been enhanced in several ways. The boom and arm, deeper in cross-section to accommodate higher digging forces and intermittent hammer use, now incorporate V-groove-type welds that are placed by robots and 100 percent ultra-sound inspected. The boom-foot and boom-to-arm pivots use improved bushings, new plated pins and new dust seals that combine, says Case, to make a more durable, easier-to-maintain assembly. (These joints require lubrication only at 1,000-hour/6-month intervals.) New hardened-chrome pins used elsewhere in the digging linkage are intended to contribute further to overall digging-linkage durability.

Although the basic six-cylinder, 8.3-liter engine in the CX330 has been used in Case products since 1985—a tried-and-true powerplant, says Case—continual refinement over those years has changed 85 percent of the original engine's part numbers. Running in the CX330 at 259 net horsepower with an air-to-air intercooler and a free-breathing 24-valve cylinder head, the new Case 6TAA-830 engine's premier feature is its CAPS (Case Accumulator Pressure System) fuel system.

Even though the new fuel system is not technically a common-rail type, it does (like a common-rail system) use accumulators to store fuel at extremely high pressures. The timing and duration of injection, as we understand the system, are controlled by a rotary distributor, which is supplied by the accumulators and controlled by two communicating computers. Case calls the new engine a "full-authority, digital-electronic" type, and says its outstanding qualities are a clean exhaust stack and exceptional fuel-efficiency.

Electronic logic controlling the new engine's fuel system tracks machine operating parameters and keeps the system continually armed to respond instantly and precisely to the fuel requirements of individual cylinders. The engine's total electronic design also eliminates cable and step-motor controls from the fuel system, with a subsequent gain in reliability.

Although modest changes in the CX330's digging-linkage geometry contribute to its higher digging forces, the machine's big gun in the trench is refinement of its open-center hydraulic system. Main pressure in the implement circuit is up nearly 8 percent, and hydraulic-cylinder diameter is up between 4 and 7 percent.

The resulting increase in hydraulic power combines with the CX330's more-efficient linkage geometry to yield nearly 20 percent more bucket-digging force and 15 percent more arm force. And with 19 more net horsepower, the CX330 can drive its main hydraulic pumps with greater force. Plus, its new pumps produce about 6 percent more flow for increased hydraulic speed at lower system pressures.

Case's new Pro Control System (PCS) manages the CX330's hydraulic system and its interface with the 6TAA-830 engine, and does so with considerably more electronic intelligence than did the 9050B's control system. Like the 9050B, the CX330 does have manually selected working modes (it has three, the 9050B had four), but the CX330 departs from its predecessor's design by adding a new Automatic work mode. Working in the Automatic mode, the CX330 can analyze load demands and operator input at the joysticks, then adjust the engine and hydraulic pumps to "balance power and speed with efficiency and economy."

Other PCS features include a high-speed assistance system, which speeds up boom and arm functions, and an automatic power-boost system. The latter increases main pressure 10 percent for 8 seconds if the implement system reaches standard relief pressure for more than 1 second in tough digging. PCS also allows the operator to engage a cushioned-stop feature for the boom and arm, a new system that cushions stops at any position in the cylinders' travel, not just at the end of the stroke.

And to expand hydraulic flexibility, the machine is available with three auxiliary hydraulic kits, which are operated by fingertip controls at the joysticks. Boom and arm circuits now also incorporate anti-drift valves, and an optional pattern-selector valve allows quick rearrangement of joystick functions, a capability especially valuable in rental operations.

Complementing the CX330's refined structures, engine and hydraulics is its new cab. Even though air conditioning was optional on the 9050B, it's difficult to fault the machine's spacious, comfortable cab. The CX330, however, manages to take operator comfort and convenience a step further, with such amenities as programmable climate-control and 14 percent more glass for enhanced visibility.

A new instrument panel for the CX330 efficiently consolidates controls into the sill of the right widow, and the panel's large LCD message screen provides both operating information and easy access to self-diagnostic service codes. The cab-exit safety bar stows neatly within the left console, and the consoles themselves adjust independently of the seat via fingertip controls. And when performing overhead work, the seat tilts rearward for a better view through a larger skylight.

We asked guest operator Brian Torgerson what differences he noticed most after trenching with the CX330 and 9050B back-to-back in the tough material at the site:

"When digging close to the machine, the 330 kept level, but the 9050 felt light. The 330 got to grade faster and was much easier to use when keeping the bottom clean. It was also stronger out of the hole, and overall, it felt faster. I thought the new machine was smoother, visibility was better, and it was considerably more quiet."

Case's Russ Wadzinski had some similar observations and, like Torgerson, first mentioned the CX330's greater stability:

"The 330 was very stable in all positions when trenching in this heavy clay, and even when the auto power boost engaged, the machine pulled through the material without lifting the tracks. I really noticed the difference in stick power between the two models and, in my opinion, the 330 is smoother and more controllable."

**Compares rated capacity with measured average bucket load during test

| Lift Comparision (Over front) | ||

| 9050B | CX330 | |

| Maximum radius (ft.) | 22 | 25 |

| Advantage | 13.6% |

*Averages for 24- and 33-ft. radii