“We know where we want to go with telematics,” says Doug Buchanan, technical services manager for Honnen Equipment, Commerce City, Colo. “It’s unplowed ground, so we don’t necessarily know how to get there.”

Buchanan’s honesty accurately describes the current thinking among distributors. They recognize the potential for providing product-support services to their customers, but it is new territory.

The distributors who are leading in the transition have integrated telematics into existing product-support structures. That’s the direction Honnen is heading.

“Telematics is going to be the norm,” Buchanan says. “It’s an anchor technology for us, so we can leverage the whole enterprise.”

In April, we asked equipment buyers about their relationships with distributors. Of the 94 who completed our online questionnaire, 55.8 percent represented fleets with 25 or fewer machines; 30.5 percent with fleets between 25 and 999 machines; and 7.4 percent manage fleets with more than 1,000 machines.

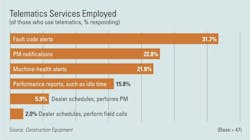

Only half of those responding said their distributor offers monitoring services via telematics. Of those respondents, 8 percent said their dealer schedules and performs preventive maintenance and/or field calls.

Distributors must close the gap between the demand for product-support services driven by telematics data, and the ability to provide those services.

The Association of Equipment Management Professionals (AEMP) has long espoused the Equipment Triangle (end-users, manufacturers and distributors work together for their mutual benefit), but distributors have been the weak leg, with only a couple regularly participating with the organization.

Based on attendance at AEMP’s Annual Conference in Orlando last month, however, that may be changing. Most of the dealers were large companies affiliated with the major OEM brands, but they recognized the importance of engaging with equipment managers who were actively involved in implementing telematics capabilities in their fleets. Rubbing shoulders with end-users and listening to presentations on telematics will pay off for these dealers.

We commend AEMP for providing the venue for some serious telematics discussions last month. The organization, led by Stan Orr, has tirelessly kept the equipment manager’s interests at the forefront as telematics capabilities have grown over the past 10 years.

About the Author

Rod Sutton

Sutton served as the editorial lead of Construction Equipment from 2001 through 2025.