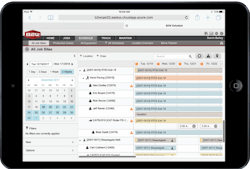

B2W Software Schedule

B2W Schedule centralizes resource planning, scheduling, and dispatching processes and moves them online to allow real-time collaboration.

It will allow users across workflows to assign and view crews, labor, equipment, and material resources on desktop or mobile devices with customizable one-day, multi-day, or multi-week views. Individual users can manage scheduling based on their areas of responsibility—from scheduling crews and setting daily production targets to initiating requests and filling resource needs. The tool enhances the company’s ONE Platform, which also includes unified elements for estimating, field tracking, equipment maintenance, and data capture and analysis.