At Your Service

- Refining the crane

- Less stress, more durability

- Practical buying

- List-Price Ranges

- Crane Service Bodies and Service Cranes+

- Stellar Industries

- Maintainer

- Stahl

- Feterl

- Omaha Standard

- Dakota Bodies

- Service Trucks International

- Knapheide

- IMT

- Reading

- Auto Crane

Maybe you've been there — in the middle of nowhere, all alone, with a cold wind chilling your bones as you try to pull a transmission up through the ROPS of a big earthmover. The life of a field-service technician can sometimes be quite lonely. And on those occasions, a well-equipped service truck with a capable crane may be the best friend around.

Fortunately for the world's field-service technicians, the selection of crane service bodies — and the telescopic-boom cranes that accompany them — has never been better. A number of manufacturers have been busy refining the design of crane bodies for greater strength, durability and operator convenience, while also reducing weight and (consequently) increasing cargo capacity. The telescopic-boom cranes used with these bodies also are being continually refined, yielding more lift capacity in a lighter-weight package that provides more line pull and faster line speeds.

"Controlling weight, while maintaining lift capacity, has really come into play in the design of these vehicles," says Tim Worman, product manager at IMT. "In some instances, cargo capacity is critical, so the real focus of design has become maintaining a structure that can handle crane requirements, yet allows for maximum payload."

According to a number of crane-service-body manufacturers, leaner designs that yield more lift capacity and more payload appeal to a growing segment of buyers wanting capable packages that weigh less than 26,000 pounds, in order to avoid the commercial driver's license and attendant paperwork. But thrifty buyers also are concluding that leaner designs can yield economic benefits, in terms of lessening the load on the host vehicle, and subsequently, significantly reducing both routine operating expenses and repair costs. Plus, keeping the vehicle street-legal when hauling heavy loads avoids potentially big fines.

Many of today's service cranes have been refined to incorporate a number of accommodating features, including radio-remote control, which may, in fact, be standard equipment on certain models. According to some manufacturers, radio-remote technology has become both reliable and affordable, making it a good system for simplifying crane control by eliminating the tether. But tethered control is still usually available for users who may work in radio-restricted areas.

Crane refinement in other instances may encompass changes in basic structures, such as the use of booms with a hexagonal cross section. According to Stellar's Gary Hanson, the "hex" design provides added strength, as well as reducing longitudinal flexing and side-to-side movement. A number of crane booms also now use a "flip sheave," — a sheave block at the tip of the boom that can be rotated from its normal perpendicular position to a position in line with the boom to facilitate reaching into confined areas.

Many service cranes today also exhibit substantially increased line pull, resulting mainly from refined hydraulic-drive systems that boost pressure and flow in the circuit controlling the winch drive motor. Hydraulic refinement, say some manufacturers, also enhances a crane's "restart" capability, that is, the ability to stop a load in mid-lift, then to resume the lift in a positive fashion.

Yet another relatively recent change on some units is positioning the winch on the crane boom, instead of on its stationary base. Those that use boom mounting contend that this arrangement minimizes the risk of snapping the load line or damaging the boom, especially when stowing the crane. With the winch on the boom, the length of the load line between the winch and a hook stowed on the boom remains constant when raising or lowering the boom. With a mast-mounted winch, the operator must remember to compensate for changes in line length.

All manufacturers of legitimate crane service bodies use a means of channeling the crane's weight and the lifting stresses it creates away from the body and the vehicle chassis. One method physically separates the crane-mounting structure from the rest of the body and connects this structure to a stout sub-frame (between the body and vehicle chassis) that directs forces into the outriggers. Other manufacturers use an "integrated" design approach, in which the crane-mounting structure is not physically isolated from the body, but still employs substructures to channel forces away from the body and into the outriggers.

But what you typically want to avoid, says Walt Van Laren, sales manager for Service Trucks International, is a utility body that has been reworked to accommodate a crane. Although these reworks may be skillfully done in some instances, says Van Laren, some are not, and crane forces will exact a toll on the integrity of the body and the vehicle chassis.

Auto Crane's Kyle Whiteis agrees: "Beware of bodies modified for a crane after the fact. When smaller cranes are installed on a service body that is not designed for a crane, the body may be reinforced, but all the stress still goes through the body."

In addition to refining the crane-mounting system, a process enhanced with such tools as finite-element analysis, most all other aspects of the body continue to be scrutinized by manufacturers in an effort to improve durability and operator convenience.

Included on a long list of such enhancements are larger, stouter workbench/bumper arrangements, material of heavier gauge for compartment structures, improved hinges and latches, improved corrosion-resistance measures and rain gutters. Also on the list are more weather-resistant electrical systems that feature diagnostic capability, easier-to-trace wiring and wire routing that avoids vulnerable spots.

As you may know, service cranes typically have both a foot-pound rating and a maximum rating. But from what CE gathered from conversations with several manufacturers, the position of the crane's boom when determining these ratings may vary from manufacturer to manufacturer. Some feel that the foot-pound rating (defined as the load in pounds, which, when multiplied by its respective distance from the centerline of crane rotation, yields the greatest value) is most practically determined with the boom in a horizontal position.

The maximum rating (such as when saying "this is a 10,000-pound crane") may be determined at the crane's minimum radius, that is, when the boom is at its most vertical position. If so, you may want to ask where this radius places the hook. Is it so close to the body that lifting is impractical? A manufacturer that determines a maximum rating at a practical radius may have a lower number, yet equal or exceed the foot-pound rating of a crane with a theoretically higher maximum capacity.

Based on what we heard from manufacturers, probably the best way to decide how much crane you need is to determine what loads you're handling and at what distances. Then, look at the crane's load chart, which correlates capacities with lifting distances (radii), to determine if the crane has enough capacity (and reserve capacity).

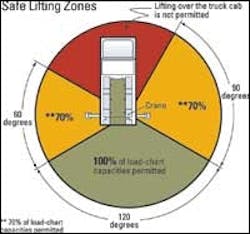

When you are checking the load chart, also take a look at the accompanying "quadrant of operation" diagram, which looks like a pie chart. This diagram graphically shows you how the crane's capacity ratings may change as it rotates around its base. You might find, for instance, that capacities stated in the load chart must be reduced by 30 percent or more when lifting over the side of the truck.

A note here about electric versus hydraulic cranes may be useful. If a small crane (usually with rated capacities of 6,000 pounds or less) suits your needs, you may find both electric and hydraulic models available. Both IMT's Worman and Auto Crane's Whiteis caution that electric models usually are designed for intermediate duty, and that a hydraulic model may be the better choice if the crane is to be used regularly. Electric models are less expensive, but typically require a high-amp alternator and a dual-battery setup.

The size of the crane, say manufacturers, basically determines the minimum standards for the service body, which also has a "foot-pound" rating (determined by the manufacturer) that must correlate with the crane's rating. The size of the service body, in turn, determines minimum standards for the vehicle chassis. But, when sizing the chassis, keep in mind the weight you may add with equipment such as welders and air compressors.

You can, of course, rely on the manufacturer or the truck-equipment dealer to select a chassis that meets your needs. Or, you may elect to purchase your own chassis locally (usually to ensure you'll get good service from your local dealer).

But if you're buying your own chassis, Feterl Manufacturing's Darrel Gstohl recommends that you discuss required specifications with the manufacturer or truck-equipment dealer beforehand. A smaller chassis, in particular, he says, may not routinely be equipped with features needed for crane-service-body application, such as a transmission-mounted PTO, and must be specified when ordering the truck.

| Web Resources | ||

| Crane-Body Manufacturers | ||

| Auto Crane www.autocrane.com | Dakota Bodies www.dakotabodies.com | |

| Feterl www.feterl.com | IMT www.imt.com | |

| Knapheide www.knapheide.com | Maintainer www.maintainer.com | |

| Omaha Standard www.omahastd.com | Reading www.readingbody.com | |

| STI www.servicetrucks.com | Stahl www.stahl.cc | |

| Stellar www.stellar-industries.com | Service-Crane Manufacturers | |

| Flannegan Western www.fwcrane.com | Ideal Crane www.idealcrane.com | |