Wringing Huge Work Out of Compact Excavators

- New Holland

- Doosan Infracore

- Volvo

- Case

- Caterpillar

- Komatsu

- Kobelco

- Ingersoll Rand

- Yanmar

- Hyundai

- Gehl

- Terex

- Mustang

- John Deere

- LBX

- Takeuchi

- JCB

- Hitachi

- Specifications: 15- to 20-Ton Excavators (by weight)

More than 45 hydraulic-excavator models between 20,000 and 40,000 pounds compete for your purchase dollars. Enough money is being spent on machines this size that the scent of cash and desire to supply the big rental houses attracted no less than four manufacturers to field their first excavators in the size class over the past 30 months.

Four of the six models brought to market by new competitors Ingersoll Rand, Takeuchi, Terex, and Yanmar combine features in a way that's indicative of why the excavators in this size class can be King Kong compacts. They're nearly-100-hp machines with features common to compacts such as swinging (or articulated) booms, minimum swing radius, and options for rubber or steel tracks.

Takeuchi's 31,500-pound TB1140, for example, is the largest excavator in the North American market whose standard equipment list includes a boom mounted to the upper frame at a hinge point like so many compact excavators. The swinging boom impinges on the machine's power somewhat (its lifting capacity over the idlers at a 20-foot radius with the load at ground level is comparable to machines that weigh a ton less). But a swinging boom allows the machine to dig a hole with sides parallel to its tracks the entire width of the machine without need for repositioning.

Caterpillar, Komatsu, and Kobelco offer alternatives to the swing boom usually called offset boom machines. These units will also excavate parallel to the tracks the full width of the machine, but accomplish it with a boom that has two joints rather than mounting a rigid boom with a hinge to the frame. Optional offset booms on Cat's 314C and Kobelco's 135SRLC actually push the feature up to the 33,000-pound size range.

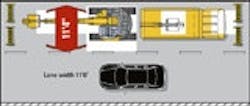

Nineteen of the 10- to 20-ton excavators available today — nearly half — are reduced-swing-radius, or zero-swing-radius machines. The counterweight and boom on these machines extend only inches beyond the track width so they can work effectively in very small or congested areas without risk of swinging into obstacles. Manufacturers produce reduced-radius machines by installing a larger counterweight and changing frame geometry to preserve lifting and digging capacity.

Most machines in the class were upgraded to the latest technology in 2003 and 2004 when they had to comply with EPA's Tier 2 emissions regulations. Reduced-swing-radius machines have dominated new introductions since then.

"There is increasing demand in certain applications for zero swing machines to work in smaller and smaller spaces, while maintaining high outputs," says Dave Hardwick, excavator product manager at JCB. "The push to constantly reduce the build time on developments has increased the need for high output, high efficiency machines that can carry out large amounts of ground works and utility works every day."

The heaviest reduced-radius excavator in this class is Komatsu's 36,400-pound PC158USLC-2. With an 8 foot-2 inch stick, it can pick up 8,700 pounds at a 20-foot lift radius. But reduced-radius excavators do sacrifice some digging and lifting leverage in order to get a shorter upper frame.

Comparisons are telling. Komatsu's reduced-radius PC138USLC-2, at an operating weight just under 31,000 pounds, develops stick-digging force of 13,670 pounds. The conventional PC120LC-6 (3,200 pounds lighter) applies 13,890 pounds of stick-digging force.

John Deere's reduced-radius 135C RTS, with an operating weight of 30,400 pounds, moves the stick with 12,800 pounds of force. The 28,800-pound 120C (1,600 pounds lighter) develops 13,172 pounds of stick force.

"As customers continue to look for improved efficiencies in their business, smaller