Work Order Codes Drive Data

A work order coding system exists not simply because the computerized maintenance management software (CMMS) has a field to be filled in. It exists to provide information required to run your business. Before you design and develop it, you absolutely must decide on your key performance indicators (KPI) and your data requirements. If you want to know how much money you spend on capitalized undercarriage rebuilds, then you must have a work-type code for capitalized rebuilds and a machine-component code for undercarriages. If you have no interest in how much you spend on capitalized rebuilds or on undercarriages, then there is no need to include these codes in your system.

No single work order coding system will work for all companies and all types of machines. Every company is different, every machine type is different, and every company uses information to measure and improve performance in a slightly different way. Every coding system must be designed and set up to produce required data and suit a given situation.

The diagram above helps to understand how a coding system should be developed.

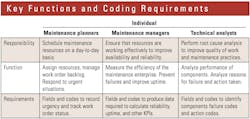

Step 1 starts the process by identifying the principal functions and individuals involved in the fleet-management process and by defining the information they need to be successful. Maintenance planners and individuals responsible for scheduling technicians on a day-to-day basis must know the urgency of the work and the status of work orders in progress. Maintenance managers must know that resources are being effectively utilized, and technical analysts responsible for root cause analysis must have detailed statistics on failure codes at a component or sub-component level. The key point is that you must know what information is required for individuals to be successful in their job. The work order coding system must be designed to produce this information—no more and no less.

Step 2 defines the KPIs used to measure and improve performance. Requirements are different for each function and each individual. Maintenance planners look at information such as PM schedule compliance and days of work in backlog, while maintenance managers use indicators such as percentage of technician time spent on scheduled and preventive maintenance and the frequency of reported emergency down events. Carefully defined KPIs are crucial for success. They also depend upon a steady supply of reliable and accurate data. This is where step 3 comes in: You absolutely must know and precisely define the data required to calculate each and every KPI. If PM schedule compliance is important, then you must know when PM schedules are due and when they are actually performed. If reliability is important, then you need to know the number of unplanned emergency down events that occur in a given period.

Steps 1, 2, and 3 are sequential inputs to step 4 and make it possible to design a system that produces the required data and meets defined needs. It is now a matter of deciding which of the various fields available in the CMMS are going to be used for a given purpose and defining the codes that will be entered into each field. There will, as a minimum, be three groups of fields and codes to serve three different and distinct purposes.

The first group of fields and codes will be used by maintenance planners to produce information needed to assign resources, manage backlog, and respond to urgent situations. Work priority codes and work status codes are minimum requirements. The second group of fields and codes will be used by maintenance managers to measure and track if the maintenance enterprise is effective in the work it does to prevent failures, improve reliability, and ensure that the fleet is up and running for the maximum possible time. Work type and reason codes will provide the data required to calculate KPIs that measure factors such as the percentage of technician time spent on preventive maintenance, the number of reported emergency down events, and the amount of money spent on abuse or vandalism.

The third group of fields and codes is probably the best known and is used by technical analysts to perform root cause analysis and identify the components and sub-components that are causing most of the problems on a given machine type. A minimum of four nested fields with component, sub-component, failure type, and action codes appropriate to a given machine type is required to find, filter, and summarize the data needed for root cause analysis. Nesting is essential in reducing the number of available codes to no more than eight mutually exclusive options.

Step 5 in the diagram follows naturally from step 4. Implementing the defined system and correctly coding work orders as they occur ensures that required data is produced in a routine and systematic manner to calculate KPIs, measure performance, and improve results.

The nearby table shows how the functions performed by individuals involved in the maintenance enterprise define the fields and codes needed to produce the information they require.

With this analysis of steps leading to coding requipements, we can conclude:

1. Although the process is logical, simple, and straightforward, many companies design and implement a work order coding system before deciding on the data they need to manage the maintenance enterprise.

2. It takes discipline and foresight to work through steps 1, 2, and 3 before going to step 4 and designing the actual work order coding system. Substantial time and talent is wasted working with a coding system that is too complicated to use consistently or too simple to produce results.

3. If you are implementing a CMMS, you absolutely must start with step 1 and work systematically through steps 2 and 3. Set clear objectives and design a work order coding system that works for you and your company. You are going to live with it for a long time.

4. If you have a CMMS system and your work order coding system is cumbersome or not producing data you need or use, start afresh. Go back to step 1 and change. A system that does not work or is overly cumbersome is worse than no system at all.

5. Make sure that your CMMS has the flexibility and robustness needed to provide the fields and codes required by maintenance planners, maintenance managers, and technical analysts.

6. There may be other demands that require work orders be filtered, sorted, and totaled in a different way. Have fields and codes available to do this.

7. Lists of available codes that are longer than 6 or 8 are unlikely to be consistently used. Insist on nested codes and define short lists of appropriate codes.

It is not long since the days of four-drawer filing cabinets full of machine history files containing multiple copies of purchase orders, invoices, and work orders. The history files told us everything we wanted to know about our fleet. We wrote things down, and we looked things up. The world seemed a simpler place; we held the data we needed in our hands, and results were summarized in one or two standard monthly reports.

Computerized maintenance management software has made all that obsolete. Data storage and manipulation have become simple but remote. You need a good coding system to bring it to hand.

For more asset management, visit the Construction Equipment Executive Institute.