How to hire technicians for the long term

Technicians are the lifeblood of the organization’s maintenance team. They execute timely and efficient maintenance and repairs on the fleet’s equipment. They analyze diagrams and schematics, and inspect for known—as well as undetected—mechanical and operational concerns. The corrective actions they take maximize machine productivity. Their diligence and documentation of maintenance and repair actions and red-event failures become the basis for the organization’s proactive approach to predictive maintenance and corrective action plans.

Attracting and hiring technical staff to meet the needs of an organization’s maintenance technician requirements is no easy task these days. Labor forecasts predict a continuing shortage of qualified applicants entering the equipment maintenance and operations labor pool over the next decade.

Managers face an increasing challenge to attract the right candidates, proceed through the application and interview processes, offer a competitive compensation package, and successfully onboard the best, potentially long-tenured technical candidates available. Managers at all levels of an equipment organization engage in the recruitment and hiring process of the organization’s technical workforce. Many only fill a handful of positions a year, limiting their experience and expertise in this process and compounding recruitment and onboarding challenges.

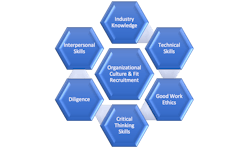

Recruitment and successful hiring are quickly becoming primary functions of equipment managers. To adapt to these increasing responsibilities, equipment professionals must revise their approach to proactive recruitment and onboarding. In addition to recruiting for experience and technical capability, managers must incorporate organizational culture and fit as position requirements.

The concept of cultural fit combined with experience and technical capability is increasing rapidly throughout the industry, specifically in filling technical positions within the equipment maintenance and management workforce. It requires an organizational transition to the recruitment of individuals with experience and technical skills to meet a specific minimum level of the organization’s requirements, and having other core or soft skills (communication, values, personality) cohesive with the existing equipment team and organizational culture. The desired outcome of this initiative is development of a long-tenured workforce with the potential to grow within the organization, increasing the efficiency and performance of the equipment function.

Cultural fit augments maintenance technical skill

A recruitment strategy centered on cultural fit over technical capability is not a new concept, yet it can boost quality and quantity of candidates and potentially become a significant influence in reducing high employee turnover as well. The inclusion of cultural fit within the organization increases the likelihood of hiring based upon a candidate’s potential, rather than just experience and technical capability. Although experience and strong technical skills are routinely most desired, hiring solely these skills can potentially create significant disruption within the work environment if the wrong candidate is brought onto the team.

The emerging workforce, and that of the future, appears prone to change employment swiftly as new and potentially more rewarding employment offers arise. Progressive organizations understand the value of making candidates feel more comfortable with the organizational culture and work environment during the recruiting process and initial stages of their employment. Those employees are more likely to desire a long-tenured career with the organization and advance as opportunities arise from within.

Core or soft skills include personal abilities and skills that complement a candidate’s technical skills. Combining core or soft skills with knowledge and experience allows the equipment manager to identify a candidate’s full potential within the organization. A weighted scale should be developed to combine soft and technical skill sets.

Key technician skill sets

Equipment managers successfully using this strategy have identified some of the essential technical, core, and soft skill sets that every successful equipment technician should possess, and what hiring managers should look for.

Industry Knowledge is imperative for all equipment technicians and professionals. It includes knowledge of machine operating characteristics, a good understanding of the various functions of the equipment team and how they interrelate to operational efficiency, and processes and procedures of efficient and effective maintenance functions. In today’s work environment, prospective candidates often come from similar industries or functions within an organization.

Hiring equipment managers should look for candidates who have researched the organization and equipment industry and have a good understanding of the cohesiveness between all equipment functions within an organization.

Technical Skills, naturally, are imperative. Technology is continually changing, and a technician needs to monitor new products and modern technologies. Technicians must have a level of technical skills sufficient to meet at minimum the entry-level technician status of the organization, focused upon the specific type of equipment operated within the organization. Additional training once signed on with the team will enhance their technical skills and allow them to grow within the organization.

Ask prospective candidates what additional training they feel they need.

Equipment technicians must display an Exceptional Work Ethic. Equipment managers and operators depend on their technician to keep their machine operational at peak performance. Technicians must be dependable, yet finding this quality in potential applicants can be challenging. A good work ethic requires responsibility, hard work, punctuality, attentiveness, and other initiatives to address all aspects of the assigned tasks completely and efficiently.

Hiring managers should ask direct questions pertaining to these areas and carefully look for candidates who demonstrate a good work ethic early in the recruitment process.

Equipment failures and repetitive problematic occurrences are not easily detected. Technicians must have innate Critical Thinking Skills to inspect and isolate various systems to successfully determine the root cause of such occurrences and take corrective actions on the initial diagnosis. This skill set develops with experience and technical capability, yet technicians entering the workforce must demonstrate sound principals of problem solving during the recruitment process.

Questions should be developed specifically to identify a significant challenge, asking the candidate to describe how they would solve the challenge.

Diligence is a critical characteristic of a great technician. Whether working on repairs, diagnostics, or maintenance, it is imperative they perform these tasks with mindfulness and due diligence. Although successful equipment maintenance and repairs keep machines working and profitable, the failure to correctly diagnose or repair something upon first notification will inhibit production, profitability, and possibly create a safety-sensitive situation in the field. Attention to even the smallest of details develops with experience and technical capability, but it must be clearly identified as a candidate’s strength.

The candidate’s response to critical thinking skills will assist in this determination. Look for analytical process thinking and a response which includes quality control measures.

Good Interpersonal Skills are needed to ascertain what is going on with the machine when a technician visits a site. Equipment operators are more inclined to communicate detailed operational observations to assist in the diagnosis and repair to someone whom they trust. Being able to effectively communicate maintenance and repair issues to operators and what they will be working on will build trust. Operators will be more inclined to quickly identify minor defects and small repairs rather than live with them until failure or the next major service interval.

Monitoring a candidate’s communication and openness to group discussions should be identified during the recruitment process. Introduce the candidate to the existing team and monitor their willingness to openly communicate.

Good technicians must be technically savvy; great technicians have core and soft skills that augment their technical skills. Technical competencies should be used as a baseline to identify the best candidate for the position. Instituting core and soft skill set competencies within the hiring process can assist in onboarding quality candidates who are a good fit for the equipment team and who can be technically trained to advance and grow within the organization.

About the Author

Mike Brennan, CEM

Michael Brennan is a 40-plus-year industry veteran and consultant in vehicle and equipment maintenance management. A three-time recipient of the AEMP Fleet Masters Award, he focuses upon process improvement, facilities management, succession planning, technology, and lifecycle analytics as the cornerstone of success in the equipment management industry.

Read Mike's asset management articles.