System Monitors Bridge Defects

A research project that supplements bridge inspections began this fall in Minnesota to monitor fracture-critical bridges and give advanced warning if any part of the bridge begins to fail.

The Minnesota Department of Transportation hired the University of Minnesota to conduct the three-phase project on the Cedar Avenue Bridge in Bloomington because it is a fracture-critical bridge, which means if one bridge element fails, the entire bridge would collapse or partially collapse. “The project looks for capable and cost-effective methods to monitor fracture-critical bridges with advanced technologies,” said Tom Styrbicki, P.E. in the Bridge Construction and Maintenance office.

This is the first research project using this method, which Mn/DOT chose with input from the University of Minnesota. “We inspect all fracture-critical bridges on a two-year cycle around the state,” Styrbicki continued. “We chose the Cedar Avenue Bridge because it’s a fracture-critical bridge that is relatively young. If we can establish an effective system, then implement it on this bridge, then we’ll have more years of use and some data to collect about the bridge’s condition. Also, this area is in close proximity to metro headquarters, the bridge office, and the U of M.”

Research on current technology

Mn/DOT hired the university as the research agent that looked at developments in technology for monitoring systems, recommended the system and not a specific brand, and suggested the type of testing.

“The University looked at many factors to develop criteria and surveyed others using a system like this. Then it applied the criteria against other systems and scored them accordingly. We came up with a numeric score that indicated the combination of factors that makes the most effective system,” said Styrbicki.

“Obviously, the pass/fail system has the ability to detect the initiation of a crack in the steel, and that’s fundamentally what we’re after.”

Phase 1 consisted of selecting a bridge and evaluating structural health monitoring techniques. Many techniques exist but none has been developed specifically for bridges, according to Styrbicki.

“We went out to canvass technologies and found what we thought was an appropriate one for monitoring a bridge,” he said. “It’s called acoustic emissions monitoring. We selected that technology and estimated the cost.

“In phase 2, which is where we are today, we purchased the system and we’ll install, calibrate and work through the details on an area of the Cedar Avenue Bridge. This is the test portion. We’re also working on a power source off the bridge and had to install solar panels as our power source for now. We had to get a cell phone contract for data communications set. We’re working towards installing the sensors, which are relatively small and are placed within the tie girder, the large box under the deck. We have to run conduit from the solar panels to the wires, link the wires together and connect them to the data box to collect data.”

The Sensor Highway, as this system is called, monitors different aspects of what can fail on the bridge, according to Terry Tamutus, director of business development, Infrastructure and Sales for the Mistras Group, the sensor manufacturer in Princeton Junction, N.J. “You can listen for cracks and corrosion in the steel, and it can tell how much the material is deforming or stretching,” he said.

How technology works

Four steel sections comprise the Cedar Avenue Bridge with 16 sensors placed on each section.

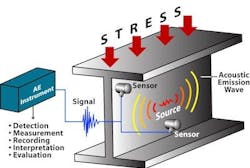

“We’re using 16 channels on a section of one of the steel beams,” Tamutus said. “The sensors are called acoustic emission sensors, which means if you have a piece of wood, steel or some material and put the material under stress, it will crack. That cracking sound travels for a long distance and travels much better because it’s traveling through material, not air.

“The sensors are more sensitive to picking up these cracks because they’re directly coupled to the material. A very high-frequency acoustic emission sensor isolates the cracking sound and doesn’t hear the ambient noise, which, typically, are low frequencies that don’t pick up vibrations,” said Tamutus.

The three partners in this project are listening for different defects on the bridge, anything from rubbing to cracking to corrosion.

“When the sensor hears a noise, it sends a signal to the Sensor Highway. The Sensor Highway interprets how loud the noise is, how long the signal lasts, and about 23 different characteristics of that signal. It distinguishes between one type of defect and another type of defect,” explained Tamutus.

Set alarms, collect data

For example, a crack is loud but lasts only a short time. Friction and rubbing on the bridge are quiet.

“The Sensor Highway system is what’s collecting and processing the signals in real time,” said Tamutus. “We set the alarms in the system to actually distinguish between the different cracks, friction, or other signals. We can use a cellular modem or a fiber-optic cable and monitor the signals through the Internet. When the system hears a sound, it can text a message to a bridge engineer who determines the type of bridge problem.”

Styrbicki said part of the research would be evaluating the effectiveness of this system.

“We’re looking for a cost-effective method before we go into full installation of monitoring this bridge,” he said. “We expect to start installation in January and will take no more than a week. Once the monitors, power, and communication are in place, we start receiving data right away and expect to pull data for a year.”

Phase 3 of the project starts after one year of monitoring. “If we see that this is an effective system, we’ll pursue full bridge monitoring on the Cedar Avenue Bridge and, later, other fracture-critical bridges in the state,” said Styrbicki.

The initial cost for materials and installation is slightly under $50,000.