Highway Pavers Trend toward Versatile Widths

Large slipform concrete highway pavers are an equipment category that doesn’t change much year to year, but this past year saw product launches from two of the major manufacturers that were marked by versatility and technology.

All the big OEMs have been hitting these themes for a while.

Most recently, Power Pavers (Power Curbers) released its SF-3404 full-width, four-track concrete slipform paver.

Read also: Focus on Asphalt Screeds for Mat Quality

“It was built with decades of knowledge and technological advancements,” says Power Curbers CEO Stephen Bullock. “Our goals are to give contractors the smoothest ride possible, save them time, and give them complete visibility around the machine.”

The Power Pavers SF-3404 concrete paver paves a maximum of 40 feet and features telescoping endpans for 2 feet of width flexibility on each end. In addition, it has a heavy-duty plow, rigid paving pans, and durable slew drives.

“These features are for additional reliability,” Bullock says.

Also new is an optional compact, fully controlled Dowel Bar Insertion (DBI) system. It is equipped with a hydraulic floating floor to maintain the integrity of the initial slab and improve reconsolidation around dowel bars after the insertion process.

“Each time the DBI runs, the carriage recalibrates with electronic sensors to ensure the floor is exactly where it should be,” Bullock says. “Also, the DBI is split to allow for accurate crowning and bar placement. Each bar is held and guided into the concrete to prevent skewing, even while crowning.”

When running the DBI system, the machine utilizes a collision avoidance system to prevent center tie bars and dowel bars from inserting at the same location.

“Our DBI is split, allowing the DBI to maintain a crown,” Bullock says. “This increases the accuracy of bar placement and reduces the amount of displaced concrete when running DBI with a crown. On the SF-3404, bars are held and guided into the slab to prevent rollaways or shifting when crowning.”

The DBI also incorporates an easy-to-load shuttle cart for simple, accurate bar placement. The goal is no jammed bars, and no concrete stuck in the feeder.

Read also: Curb and Gutter Pavers See More Use of Stringless

To create a smooth ride, the paver is equipped with the industry’s longest Oscillating Correctional Beam (OCB) for smoothing the slab’s surface after dowel bar insertion, Bullock says.

“Power Pavers has engineered a unique, heavy-duty OCB that is 30 inches tall with a 24-inch finishing length for full coverage over the dowel insertion void,” Bullock says. “The OCB corrects any surface imperfections with ease. For transportation, the DBI, OCB, OCB wiper, and final finisher are contained in a single assembly.”

There’s even more technology. A vibrator cruise control automatically adjusts the machine’s vibrators to maintain consistent speed despite fluctuations in oil viscosity or changes in concrete slump. For super-elevations and intersections, an exclusive crown-distance compensation feature provides automated crown transitions between the mold, DBI, and OCB.

The SF-3404 features Power Pavers’ signature SlipSmart control system for simple, highly configurable machine controls. All machine diagnostics are onboard, with no laptop required. The system provides fault codes for everything on the machine, including the DBI. Common bolt sizes and color-coded wiring throughout the machine are meant to keep maintenance simple.

Visibility-wise, the machine’s control panel and operator’s platform are directly above the paving pan, which means the spread auger/plow and entire grout box are in plain sight for maximum head height control. Operators have complete visibility from the platform, including the grout box, DBI, OCB, and final slab.

The DBI is mounted behind the operator’s platform, offering direct bar loading and placement visibility. The wraparound walkway offers access to both engine compartments for maintenance.

Power Pavers SF-3404 runs with a 310-horsepower Cummins B6.7 diesel. An optional 3D/GPS stringless control system offers integration with Leica, Topcon, and Trimble.

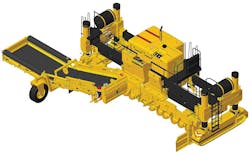

GOMACO’s GP460 was introduced at Conexpo last year. It targets wider-width operations.

As a placer/spreader with a 60-inch belt, the GP460 will accommodate widths up to 50 feet wide. As a concrete slipform paver, the GP460 will pave widths up to 40 feet wide.

It is built on the framework of the GOMACO two-track GP4 slipform paver with the ability to convert the prime mover into a concrete placer/spreader. The prime mover is equipped with vibrator circuits for paving and auger drive circuits for placing.

Controlling the technology is the company’s proprietary G+ digital control system. G+ handles the controls conversion needed for each application while also bringing onboard Machine to Machine (M2M) communication, sonic sensors, 3D machine guidance, and more.

“It’s truly the brain of the machine,” says Grant Godberson, VP of manufacturing for GOMACO. “We’ve built the GP460 on the success of our GP360, the industry’s first combination slipform paver and placer/spreader on two tracks.”

The GOMACO GP460 concrete paver is powered by a Caterpillar C7.1 turbocharged diesel engine to drive the conveyor belt and distribute concrete across the grade. The high-volume, 60-inch conveyor belt can be mounted on either the left or right side, depending on job site conditions and the location of the haul road.

It has a discharge speed of up to 492.5 feet per minute for concrete placement. A controllable material deflector directs the flow of concrete at the discharge end of the conveyor for placement accuracy. A dual-drive auger system moves the material to the center or outer areas and across the strike-off.

The GP460 is available with an optional sonic sensor system to monitor the concrete depth as it is placed. Information from the sonic sensors is utilized by the G+ control system on the paver using M2M communication to provide an optimum and consistent head of concrete in front of the paver.

Wirtgen’s last big introduction included the two-tracked SP 102i, which features an extended maximum working width. Wirtgen says its fully modular construction concept allows the machine to quickly adapt to meet the requirements of different construction sites by adding or removing the required modules.

Paving can take place from 16 to 40 feet wide.

In addition, an intelligently-designed concept ensures that all components–including the spreader plow and the super smoother–can remain mounted on the machine during transport. This means that the inset slipform paver takes less time to setup prior to starting work.

Efficient engine management also contributes to the economical operation of the machine. When the user selects ECO Mode, the power management system automatically adjusts the engine speed based on the horsepower required, and in turn, reduces fuel consumption.

ECO mode ensures that the Tier 4-F-compliant, 310-horsepower diesel engine always runs at optimal speed.

The user interface of the Wirtgen SP 102i concrete paver features control panels with language-independent graphic labeling of all control elements. Wirtgen says they are identical on all the company’s slipform pavers and that reduces the need for training and familiarization of operators working for the first time with the various models.

The ergonomically designed operator’s platform provides an overview of the entire construction site, Wirtgen says, and a hydraulically height-adjustable weather canopy protects the operator against sun and rain.

An oscillating super smoother is designed to ensure high surface quality of the up to 18-inch-thick concrete layers. These can have crown profiles with a cross slope of up to 3%. As an additional option, two side dowel bar inserters place anchors into the fresh concrete to prevent adjacent lanes drifting apart.

The machine is equipped with hydraulic vibrators for compaction. They evenly compact the concrete for a homogeneous structure. In addition to the 18 factory-fitted hydraulic connections for vibrators, the inset slipform paver can also be equipped for the connection of 24 or 30 hydraulic vibrators for greater working widths as an additional option.

The paver’s 3D interface can be used in combination with a 3D system and total stations from various providers for paving results based on pre-determined planning data.

With the WITOS FleetView telematics system, the SP 102i also provides remote support for machine fleet managers. This makes the planning and execution of required maintenance easier, in addition to providing performance data such as current fuel levels.

The last major redesign from Guntert & Zimmerman involved its S600 slipformer.

In addition to a Tier 4-F engine, it received enhanced width capability, a theme with recent introductions in the category. A VariWidth tractor frame allows width changes from 8 to 22 feet in a few minutes.

This happens with the help of patented camber adjusting, support rollers, and a hydraulic clamping puck system. The hydraulic clamps lock the male telescopic tubes in a fixed position relative to the center module to produce more accurate steering.

G&Z’s patented tunnel in the bolster design (through which male telescopic tubes can pass) offers a wide telescopic range. This design eliminates the need for two-stage, telescopic extensions per side that the company says may sag at wider widths and impact desired steering and grade control.

To change the tractor frame width, the paver operator flips a switch to release the hydraulic clamping pucks on one side of the machine. Then, using the crawler tracks in the 90-degree steering mode, the operator walks the tractor frame out to the desired width, supported by the rollers. There is no need to support the tractor frame center module prior to telescoping.

A Caterpillar C7.1 302-horsepower engine powers the paver.

The redesign also included improved serviceability with better access to the pumps and filters. The diesel fuel tank (along with the DEF tank) has been relocated off the end of the Power Unit. The Power Unit electrical and hydraulic filtration systems have been completely upgraded and include enhanced monitoring of hydraulic circuits flow, pressure, and filter condition.

“I think what you’re going to continue to see in the future is more technology and streamlining to make pavers easier to set up and run,” GOMACO’s Godberson says.

“Time savings is going to come from that fast set up and the increased versatility to adapt to different jobs, and we all know time is money.”

About the Author

Frank Raczon

Raczon’s writing career spans nearly 25 years, including magazine publishing and public relations work with some of the industry’s major equipment manufacturers. He has won numerous awards in his career, including nods from the Construction Writers Association, the Association of Equipment Manufacturers, and BtoB magazine. He is responsible for the magazine's Buying Files.