Leases Keep Fleet Under Warranty

Silt fences that border construction sites prevent topsoil from washing away. Yet the familiar fencing is only one of several erosion-control measures used to comply with National Pollutant Discharge Elimination System (NPDES) regulations of the U.S. Environmental Protection Agency.

Project owners and general contractors often rely on specialty contractors such as Rich Erosion Control to install and maintain systems that prevent or control erosion caused by storm-water runoff.

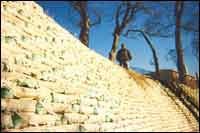

Owner Mike Rich started the business eight years ago with two employees and a truck. Revenues have increased about 45 percent annually with a growing client list of developers, general contractors and municipalities. In addition to reinforced and nonreinforced silt fencing, Rich performs a full range of services including topsoil relocation and fine grading, erosion-control blankets, seeding, hydromulching, temporary irrigation, inlet protection, and constructing concrete bag walls and rock check dams.

A typical project can include brush hogging and site clearance; contouring the land; fine grading; and broadcast and drill seeding, hydromulching, and fertilization to establish and maintain ground cover to hold soil in place. Walls of concrete bags stabilize and protect vulnerable areas from erosion; rock check dams prevent runoff from carrying silt from jobsites.

Rich's fleet includes conventional construction equipment and specialized machines, including eight Bobcat and Caterpillar skid-steer loaders, two John Deere tractors, one Bowie hydromulcher, one Ditch Witch and one Burkeen trencher, an irrigation reel, and seven crew trucks and trailers.

Skid-steers are the workhorses of the fleet, Rich says. "They are very mobile," he says. "With the selection of attachments available today, they can do so many jobs; they are more cost-efficient for us than any other machine."

When acquiring new equipment, Rich looks for durable, dependable machines that have a reputation for quality and are made by companies that stand behind their products. Rich Erosion leases and owns equipment. When needs for other equipment arise, Rich rents or leases and returns the machine when its work is completed.

"Generally, we find two-year leases to be best," Rich says. "At the end of the lease, we turn the machine in and get a new one. That way, equipment is always under warranty, so we have no repair costs. Our only operating costs are insurance, fuel, oil and other fluids, and filters. We have the benefit of operating new equipment, which avoids the downtime that happens when you operate old machines."

Crew leaders are responsible for routine maintenance, including changing fluids, tire changes, brake jobs, and replacing wear parts. They report damage to Rich's in-house mechanic. Equipment dealers do warranty repairs and provide brand-name lubricants and OEM parts to keep warranties in force.

A computerized maintenance-control system provides alerts when service is due and maintains service records on each piece of equipment.

Rich says increased demand for erosion-control services has increased competition in the market, but he says his company's experience and reputation for quality work give it a strong advantage.

"We do quality work, are dependable, and have excellent relationships with clients," he says. "We plan to continue to grow and are on a pace for 2003 to be our best-ever year."