Know Your By-Pass Filtration Basics

First, to clear up a common misconception, "by-pass filtration" has nothing to do with the by-pass valve in your engine's primary oil filter. That valve is there simply to open and maintain oil flow to the engine if the filter clogs. By-pass filtration (a better term might be "partial-flow" filtration) is a process that continually diverts a small stream of the engine's oil, usually about 10 percent, through a supplemental cleaning system. Even though the supplemental system might process, say, only two gallons per minute, it's designed to clean the oil more thoroughly than the engine's primary ("full-flow") filter. Cleaner oil, say proponents of by-pass filtration, reduces engine wear and promotes extended oil-drain intervals.

Decades ago, when the concept of by-pass filtration was developed, the process was called oil "polishing." Back then, when oil filters were not terribly efficient, by-pass filtration was used on all sorts of vehicles to keep oil cleaner, thereby reducing engine wear and buying more time between overhauls. But as conventional oil filters became more and more efficient, use of by-pass filtration declined. Nonetheless, the by-pass-filtration concept not only has endured all these years (remaining especially popular in remote parts of the world where oil and filter quality can be inconsistent), but also has been refined.

Today, a number of by-pass-filtration systems are available, and interest in them is on the rise. The prospect of new-generation engines dumping more contaminants into the oil, because of their advanced emission-control systems, seemingly has renewed concern about engine wear, oil life and subsequent oil-drain intervals. Even though a new oil classification, CI-4, has been developed in anticipation of tougher working conditions within these new engines, by-pass filtration is being investigated as added insurance against wear and shortened drain intervals, which many engine users have worked hard to extend.

Two basic types of by-pass-filtration systems are available today, those that use a filtering element, and those that employ centrifugal force.

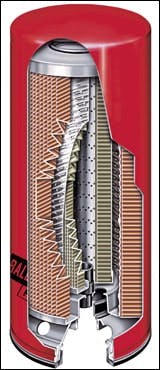

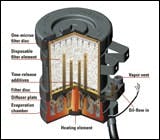

Element-type filtration systems typically use a natural- or synthetic-fiber media (filtering material) that is designed to trap contaminants smaller in size than those caught in a conventional full-flow filter.

If by-pass-filter media is the depth type, it consists of a tightly compressed network of fibers, including blends of cellulose (plant fiber) and graded wood chips, blended yarns of cellulose and cotton, compressed cotton, synthetic materials and synthetic/cellulose blends. These materials form a deep maze through which oil must find its way.

Most formulations of depth-type media are good at removing organic contaminants, often called "sludge," which contains resins and combustion by-products, sometimes combined with soot. Some say that these engine-wearing organic contaminants constitute the bulk of an oil's impurities, and that trapping them helps keeps the full-flow filter cleaner and more efficient at removing larger, more abrasive particles of inorganic debris.

Element-type media also may take the forms of pleated paper (cellulose), which catches contaminants on its surface, or stacks of thick paper discs that may combine aspects of both surface and depth filtration.

The media may be contained in a remote-mounted housing (located on a truck's frame, for instance) as are the Luber-finer, puraDYN and OilGuard systems. Or, the by-pass media can be contained in a separate spin-on canister, such as in AMSOIL's Dual-Remote system, which replaces the engine's original full-flow filter with two remote-mounted spin-on canisters, one full-flow, the other a by-pass. Another variation for housing the by-pass media is to package it in a spin-on canister along with conventional, full-flow media, as do the "combination" filters from Baldwin, Fleetguard and Luber-finer.

Comparing contaminant-stopping ability between full-flow and by-pass media is a little dangerous, because definitions and claims vary widely. Typically, ratings are given in microns, one-millionth of a meter. (Human hair averages 70 microns in diameter). But you have to know whether the rating is "nominal" (trapping 50 percent) or "absolute" (trapping 98-plus percent) of a given particle size.

Keeping that qualifier in mind, you'll likely see conventional, full-flow filters with ratings ranging from perhaps 5 to 40 microns. A premium full-flow filter may, for example, have an absolute rating in the mid-teens. On the other hand, ratings for by-pass media may range from 20 microns to less than one micron. Claims for some by-pass media also include the ability to absorb (or neutralize) acids and sulfur compounds, and the ability to remove soot.

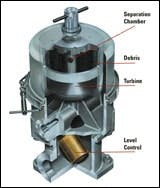

The centrifuge-type by-pass system, as its name implies, uses centrifugal force to clean the oil. Spinning at 5,000 to 6,000 rpm, these centrifuge systems, such the Fleetguard ConeStaC and the T.F. Hudgins Spinner II, separate contaminants from the oil by flinging them outward and depositing them on the perimeter of the centrifuge chamber. The deposited contaminants eventually build into a thick, compacted cake that is periodically removed. At least one centrifuge system claims solid-particle removal down to one-tenth micron.

According to those who are convinced of by-pass filtration's effectiveness, you're always better off, in terms of protecting the engine from wear, by using a by-pass cleaning system, no matter how effective your full-flow filtering system may be. And, although the more moderate of these proponents would admit that the use of by-pass filtration doesn't automatically guarantee extended oil-drain intervals, all believe that employing such a system can be a key element in achieving that end.

But on the other hand, some would make the point that you can accomplish similar goals, without the added expense of by-pass filtration, by using premium full-flow filters and good oil. Donaldson, for example, markets certain products in its Endurance filter line (using the company's synthetic Synteq media) directly against certain combination-type by-pass filters. We're also told that one oil manufacturer guarantees 60,000-mile drain intervals for truck engines using its oil and branded filter, an all-synthetic full-flow.

A criticism sometimes also leveled at certain by-pass systems is that the additional oil needed to fill them accounts, by itself, for many of the claimed benefits. Adding more oil has the net effect, they say, of increasing the engine's sump, translating into more contaminant-holding ability and the subsequent potential benefits of less wear, longer drain intervals and lower operating temperatures. Plus, when the media in the by-pass filter is changed at scheduled intervals, say critics, a sizable volume of make-up oil may be required, which helps renew the sump with fresh additives.

Critics also question the claims of acid-neutralizing and soot-catching ability made by manufacturers of some by-pass systems. On the soot issue (soot is carbon particulate resulting from combustion), the critics maintain that particles are so small, just a tiny fraction of a micron, that no by-pass system, either element- or centrifuge-type, can remove them. Soot control, they say, is a function of the oil, which is designed to keep particles in suspension.

Some proponents of by-pass cleaning, however, take issue with the critics about the claimed inability of centrifuge systems to remove native soot and other organic compounds, saying that some systems do, indeed, have this capability. Although proponents would probably agree that filtering soot in its native, sub-micron state is next to impossible, they would claim for depth-type media the capability to remove soot in its "agglomerated" (clumped-together) state. In this state, soot becomes potentially an abrasive agent and thickens oil, shortening oil life and sometimes jeopardizing fuel economy.

Overall, prices for by-pass cleaning systems may range from perhaps $30 for a combination filter, to $2,500 for a centrifuge system used on a 30-liter engine. Centrifuge systems for smaller engines may range from $200 to $1,500, and element-type systems may cost from $100 to $500.

If you're thinking about a by-pass cleaning system, the best advice we heard was three-fold. First, decide what you want to accomplish by adding a system; for instance, extended drain intervals or longer engine life. Next, if possible, calculate a return on your investment (being sure to include what you'll spend replacing elements). Then, carefully evaluate manufacturer claims, asking for supporting test data if claims seem particularly optimistic.