Integrating the Maintenance Enterprise

The best thing about my job is that it gives me an opportunity to spend time with the best and the brightest in our business, work on real problems, and, one way or the other, come up with a solution. These articles—this is No. 145 stretching back to October 2003—are the result of being able to do this, and I thank you all for the inspiration provided and for good times shared.

This article is no exception. It follows on some recent conversations about the maintenance function and the fact that equipment executives manage much more than machines. We manage a substantial, complex and incredibly dynamic maintenance enterprise that provides the company with the tools it needs to be successful. It is more than the tasks we perform in the field, the shop, or the yard. It is how we put it all together and make the whole thing work.

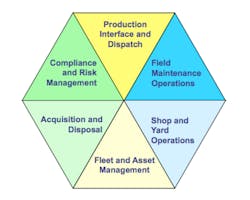

The diagram takes us back to the hexagon. As you can see, it brings together the six basic functions of equipment management and shows how the three lower left triangles (fleet and asset management, acquisition and disposal, and compliance and risk management) make up the office or clerical functions while the three upper right triangles (production interface and dispatch, field maintenance operations, and shop and yard operations) make up the field or maintenance functions.

Previous articles have dealt with the three lower left triangles. Let’s look now at the three triangles at the upper right. These define the maintenance enterprise, and it is in this area that we have substantial ability to improve performance.

Let’s consider first the yellow triangle at the top: production interface and dispatch. We absolutely must have the right equipment in the right place at the right time. That means we must know what is happening on the job sites: when machines are required, when machines will be available, and when we have to move units from place to place. It is not easy to gather the information we need to plan and manage this function as everything changes constantly. In the good old days, we used big magnetic white boards to show which units were where and to plan future moves. The displays were elementary, but all the information was in one place and, in order to make the system work, we had one person in charge of the dispatch board. Information was centralized, and strategies were developed by field and shop personnel sitting together in the “war room” to agree on priorities.

Those days have passed. We now have competent software to handle the dispatch and resource planning function. We can slice and dice the dispatch board in almost every way imaginable, and almost anyone can participate in the decisions and priorities used to allocate resources. It is a blessing and a curse. More people can participate in the process, and we can do it more quickly. But we lose single-point control and we lose the quiet cooperative thinking needed to develop the right strategy. Most importantly, we lose the discipline needed to ensure that the “planning board” keeps pace with the field and that every machine is where it is supposed to be. There is no such thing as a competent resource planning process that covers some of the machines some of the time.

Integrating the three triangles into a single maintenance enterprise can result in significant improvements.

Field maintenance operations is another area where competent software, well implemented and properly used, can make a huge difference. It is not easy to complete scheduled maintenance on time every time and to perform condition-based maintenance actions quickly and efficiently. The triangle sits in exactly the right place in the hexagon. Field maintenance is a combination of resource scheduling—the right technicians to the right machines at the right time—and work order work flow planning—making sure that the technicians have the information, filters, parts, and consumables needed to complete the required work in a single well planned visit. It is also about the record keeping required to ensure that service schedules are kept up to date and that outstanding work requests are combined with scheduled maintenance actions to the greatest extent possible.

The software can again be a blessing and a curse. Properly implemented computerized maintenance-management software can drive incredible improvements in the timeliness, cost, and quality of field maintenance operations. Badly implemented, it can lead to frustration and disillusion. As with dispatch, discipline is critical. Field maintenance is the key to success, and it must be done without compromise. It is often seen as a subset or step child of the shop work order system, but it is, in fact, a function of its own that interfaces and integrates strongly with both dispatch and the shop work order work flow system. It is a function that depends on the timely performance of specified tasks. There is no such thing as a preventive maintenance program that does not run like clockwork.

Shop and yard operations is the third of the three triangles that make up the maintenance enterprise. This is where work orders and inventory systems that manage cost and improve work flow planning are critical. The fact that the world is dynamic and that every day is beset with urgent needs and priorities increases the need for planning. It is not an excuse for running an operation that does nothing other than respond to the latest crisis.

It all starts by having a good system to collect and prioritize work requests that come from all parts of the organization. These must then be assembled into work orders that are prioritized and assigned to technicians only when parts and materials are available and only when the work can be done with maximum efficiency and minimum disruption. This is no trivial task. Combining work requests into efficient work order assignments and prioritizing these to minimize disruption to operations needs a detailed knowledge of both the equipment and the operations sides of the business. The importance of the work order process and the fact that work order codes provide most of the data needed to produce maintenance performance metrics means that work orders must be produced, issued, and tracked through the system with discipline and care.

The software is again a curse and a blessing. Incorrectly used it can result in a random blizzard of impossible assignments that remain “in progress” for indefinite periods. Correctly used, it can do two things. First, it can provide a mechanism to manage backlog and ensure that a steady stream of well-prepared and ready-to-go assignments is available to the technicians that perform the work. Second, it can establish the priorities needed to ensure that work is done with minimum disruption to operations.

Integrating the three triangles that comprise the upper right side of the hexagon into a single maintenance enterprise and providing it with the support personnel needed to focus on dispatch, preventive maintenance, and shop operations can build the necessary expertise, deliver significant improvements, and provide a platform for growth. This is particularly true in smaller organizations where it may not be possible to have a full-time dispatcher and a full-time service writer. This results in both jobs being badly done or randomly distributed to superintendents and technicians who have more to do than argue over resources and chase parts.

Much is achieved if the software is used to integrate rather than distribute systems. The dispatch board should be used to dispatch both machines and field maintenance technicians, and the work order system can be used to prioritize and manage workflows in the shop and in the field.

We must manage the three top right triangles as a single maintenance enterprise, and we must provide the support staff, software tools, and discipline needed to do it right, on time, every time.

For more asset management, visit ConstructionEquipment.com/Institute.