How to Build an Effective PM Program

Maybe you've been asked to build a new preventive maintenance program from the ground up. Maybe you've been asked to slap the paddles to the chest of a PM program that flat lined under a previous manager. No matter. Any successful PM program has certain common elements, regardless of its beginnings.

"Management support is the single most important part of a successful PM program," said Bill White, equipment division manager for Blythe Construction in Charlotte, North Carolina. "Without buy-in from management, any preventive maintenance program will just be hit-and-miss."

Richard Deeds, fleet manager for Brubacher Excavating in Bowmansville, Penn., agrees. "The first thing you have to do is sell the program to top management in your company. Although an effective PM program returns great rewards, it costs money and time, and requires a whole-hearted effort from all levels of the company."

Money may be a sticking point. Management tends to see costs; it will be up to you to demonstrate return. David Taber, coordinator of product technical services for 76 Lubricants and Kendall Motor Oil brands at Conoco-Phillips Co., said long-term savings come from several areas, including reduced maintenance costs, reduced replacement costs, reduced downtime and increased productivity.

Know your fleet's cost and reliability history and be prepared with some ambitious, yet realistic goals to improve them under the new program. "Most company owners understand the impact of downtime and lost productivity on the bottom line," said Deeds. "If you can show a history of money lost to unscheduled repairs, excessive downtime, and poorly running equipment, it should be easy to justify the initial and ongoing costs of an effective PM program."

Deeds said that once management embraces the program, the next challenge is to get maintenance personnel, drivers and equipment operators on board. "Point out the benefits the program offers to them and to the company." Deeds said that if the adoption of a new PM program will put an extra burden on personnel, an incentive program might help the employees warm up to the idea.

Incentives notwithstanding, employees will resent the imposition of new standards and the program will be doomed to failure unless you provide the tools they need to accomplish the program's goals. The first tool is training. "Employees managing the program should be trained to implement the program fully," said Taber. "They need to know how to analyze data, understand the results and, most importantly, take corrective actions when required."

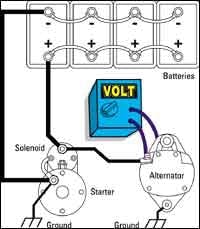

The next tool is diagnostic equipment. Unfortunately, we are at a point in the evolution of diagnostic equipment where it may be burdensome to own every tool needed to maintain a diverse fleet. Someday, perhaps, we'll have standardized tools sharing a common operating system, all talking to equipment through the same ports, speaking the same language. Right now, much of the equipment is proprietary. Worse, there are times when one diagnostic tool doesn't even work across every type of machine in a single manufacturer's product line. Still, the value of retrieving and managing data is greater than the cost and inconvenience of owning the tools. Bite the bullet. Buy the tools.

Suppose you're gathering data to drive your PM program—information such as hours of service, mileage, fuel and lubricant use. Where do you keep it? Can you manage the information without an expensive computer system?

"That depends on the size of the fleet and how much benefit you expect to receive from the system," said Deeds. "In a fleet with fewer than 70 vehicles and pieces of equipment, a basic system is adequate for tracking inspections and predicting service." Deeds said such systems typically cost from $2,000 to $4,000, including both hardware and software.

"With a larger fleet, you'll probably want a more comprehensive package that manages parts inventories, work orders, fuel use, warranty tracking and billing. It's also helpful if the system can track and cross link multiple service types." Deeds said many newer systems with these capabilities are web-based—the software and your data reside on the software-vendor's computers, and you access it via the Internet. That lowers front-end cost, but can incur a monthly fee of $500 to $5,000, depending on the size of the fleet and options users select.

Taber noted that "computers and management systems are just tools to facilitate the PM program. The quality of the program rests not only in the tools, but also in the level of commitment to the program. People have to be willing to take appropriate action when the tools tell them something's wrong."

One of the most valuable tools in your PM program is a good service truck, said White. "Our best technicians make up our PM team. They have a new, enclosed service truck with all fluids, filters and components secured inside, out of the elements. The truck has a pressure washer for cleaning equipment and lights so the technicians can work at night."

White emphasized the importance of flexible scheduling for maintenance. "We schedule production machines outside of normal work hours. At the end of the day, the crew parks equipment on level ground in an area outside the traffic flow. Our PM team arrives at 5 a.m. to complete the servicing before the crew arrives. In the case of double shifts, we plan a one-hour break between shifts to fuel, lube and perform required PM services. The job foreman and PM lead man coordinate the schedule."

And after all this, how can you tell if your new PM program is working as it should? "No surprises," said Deeds. "If unscheduled downtime rarely happens, if equipment costs are low, if equipment is operating at full efficiency, then you have a successful program." All these parameters must be quantified to satisfy management, however. "The effectiveness of your program can only be judged if you have accurate records to measure it."

Deeds' final point was that the PM program you develop must have some flexibility built into it. "If something isn't working like you planned and people are getting frustrated, you need to step back, re-evaluate, and try a different approach. And your program will have to change to keep up with changes in equipment." To stay current, Deeds recommends working closely with your equipment dealer and studying trade publications.