Gehl DL-10H/55

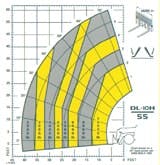

On the Gehl DL-10H/55, a longer wheelbase and all-tubular frame make it possible to lift 5,000 pounds to full height without using outriggers. However, the use of outriggers significantly improves forward-reach capabilities. When the outriggers are down, the footprint is narrower than the width of the machine, and loads weighing up to 2,000 pounds can be taken to the full 40′9″ forward reach.

The Dynattach tool-mounting system, which automatically locks onto the tool, means operators only have to get out of the cab once to unlock it. The DL-10H/55 at the Showcase displayed the optional Personnel Work Platform (PWP) system, which enables the use of an ASME/ANSI-compliant work platform in conjunction with a wireless pendant e-stop. The system is activated by depressing the brake pedal for approximately five seconds and flipping a switch located in the cab. A dash-mounted indicator light confirms that the parking brake has been automatically set, and the transmission is in neutral. Once set, the operator controls the boom functions from the cab. The worker in the platform can stop movement at any time. Radio Remote Boom Control, an upgrade to the PWP system, gives workers in the platform control of the ignition and boom functions. A trigger switch meters the speed of operation. Gehl also makes available an optional 180° manual platform rotation system.

Carraro-supplied double reduction axles deliver a tight 55° turning angle, producing a 12′2″ inside turning radius. The transmission, an electronically modulated power-shift four-speed Dana T16000, features 5-1/4-inch clutch plates. The transmission is mated to a side-mounted, 115-hp John Deere 4045T turbocharged diesel engine. The ECM protects the engine when high coolant temperature or low oil pressure occurs, giving the operator a 30-second warning before shutting down. Operation is then allowed with 30- second delays, or as long as the levels stay below the prescribed thresholds.

Sitting above and in front of the engine is a centrifugal Turbo II pre-cleaner with continuous dust collection, and engine exhaust is vented upwards to limit stirring up jobsite dust. The side-mounted engine and its service points are located under a large, lockable fiberglass cowling. The engine mount is low so once the hood is raised, all service points are handy. A master electric disconnect makes it easy for the unit to be completely disabled for security and servicing.

If you're having trouble deciding on a low- or high-mounted boom, Gehl Co., West Bend, Wis., has eliminated the need to look elsewhere. You can order either style using the company's Select-a-Boom System. The DL-10H/55 model with a high-mounted boom participated at the Showcase.

If you're having trouble deciding on a low- or high-mounted boom, Gehl Co., West Bend, Wis., has eliminated the need to look elsewhere. You can order either style using the company's Select-a-Boom System. The DL-10H/55 model with a high-mounted boom participated at the Showcase.