America's First Hydraulic Crane

In the early 1940s, Roy O. Billings, president of the Milwaukee Hydraulics Corp., saw the need for a small mobile crane that would be safer, easier to operate, and lower-priced than the heavy friction-operated cranes of the day. With more reliable, higher-pressure hydraulic systems coming on the scene, he decided to apply this new technology to his concept. He designed and built a truck-mounted hydraulic crane with a telescopic boom and hydraulically operated outriggers. He named it the Hydrocrane and launched the first model—the H-2—in 1946, as one of America's first-ever hydraulic cranes. It was a simple and highly mobile machine that became an instant success, and by the end of the following year, he had sold some 200 of them.

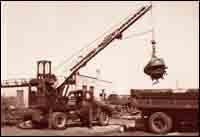

The H-2 Hydrocrane could lift two tons at an 8-foot radius and could be mounted on any two-ton truck. It could also support a quarter-yard hydraulically operated clamshell. The crane's functions were entirely hydraulic with pumps driven by a power take-off from the truck engine. The hoist motion was derived from a set of vertical hydraulic rams working between two multiple-part sheave blocks that extended and retracted the cables. From his cab, the operator could control all crane motions, including the outriggers.

The success of the Hydrocrane attracted the attention of Bucyrus-Erie Co. (B-E) in neighboring South Milwaukee, Wis. On examination, B-E's chief engineer, G.Y. Anderson, commended the machine's simplicity, safety and mobility. He specially noted the machine's hydraulic outriggers and jacks, which could be "set so quickly and easily that they are always used, saving the truck and tires, and giving the lightweight unit remarkable stability." The telescoping boom was also an attractive feature, enabling the machine to perform indoor tasks impossible with regular cranes, or lift loads through steel-framed buildings without constantly booming up and down. Anderson also noted that "..the machine would be inexpensive to manufacture and safer to operate in unskilled hands than conventional cranes."

Accordingly, B-E purchased the Milwaukee Hydraulics Corp. in 1948 and further developed the Hydrocrane concept into larger machines. In 1951, B-E replaced the H-2 with the more ruggedly constructed and heavier H-3 three-ton machine. The H-3 not only retained the mobility of the earlier machine, but could also operate as a truck-mounted backhoe known as a Hydrohoe. A larger Hydrocrane, the nine-ton H-5, and half-yard-Hydrohoe, appeared in 1955.

The H-3 and H-5 were successful products for B-E (now Bucyrus International). Over the years, they received many upgrades and were so adaptable that they lasted in B-E's product line until 1981. By then, the H-3 had been uprated to five tons capacity, and the H-5 boosted all the way to 15 tons. An array of attachments allowed the Hydrocrane to perform all kinds of crane, clamshell and excavation work. In addition to the usual truck mounting, it was available as a rubber-tired wagon crane or as a Hydrorailer, a special unit that could be driven equally well on railroad or highway. The success and experience gained from the Hydrocrane helped Bucyrus pave the way for its larger crawler-mounted hydraulic excavators introduced in 1965.

You can read more about the evolution of construction equipment in Keith Haddock's illustrated book "The Earthmover Encyclopedia," available in book stores. Also, consider a membership in the Historical Construction Equipment Association, www.hcea.net.