Quick-Change Pavers Strive for Super Paving Quality

- New tracks in asphalt

- Exhaust-control bonus

- Versatile Slipformer Specs

- Best-Selling Asphalt Paver Sizes

- Guntert & Zimmerman

- CMI/Terex

- GOMACO

- Miller Formless

- Power Pavers

- Caterpillar

- Ir Blaw-Knox

- Cedarapids/Terex

- Dynapac

- Roadtec

- Leeboy

- Vögele America

Medium-sized, variable-width concrete pavers are a reflection of a road industry given over to smaller projects. But the suddenly ubiquitous profilograph has forced another priority into both concrete and asphalt paver engineering: ride quality. Today's pavers not only must change widths and transport quickly and easily, but they also must apply finished road surfaces that hit precise standards for smoothness. It's hard to do with a structure that stretches from 10 to 32 feet.

Demand for 50-foot-wide pulls of concrete is dwindling. There's enough work in airports and western Interstates that the manufacturers of monstrous slipform machines are looking ahead to incorporating some of the flexibility tricks they've learned on their mid-sized lines in the next generation. But the emphasis is on higher-volume mid-range machines.

"As with any machines we buy, we're looking for versatility, which improves our utilization," says Dave Gorski, equipment manager with K-Five Construction in Lemont, Ill.

The quality-award-winning Chicago-area paver recently upgraded much of its concrete paving equipment. One purchase was a CMI SF-2204 with Hydraulic Variable Width. Paving width can be adjusted on the fly, much like the extending screeds so common in asphalt paving.

"There are two different segments in paving work: 1) Jobs where you're putting down base, or the surface won't have to hit a tight profilograph standard; and 2) Interstate highway where you have to be right on with profilograph measurements," Gorski says. "There's usually bonus money tied to profilograph results.

"The CMI HVW machine allows us to do the non-profilographed jobs much quicker. We are continuing to hone in on low profile numbers though; and it's great for paving tapers, access roads, and roadside aprons that narrow from 12 feet wide to 4 feet wide. We don't have to hand-pour. It is unlike any other concrete paver's utilization—we bounce it all over like an asphalt paver because one guy can move it from one job to the next in less than a day's time."

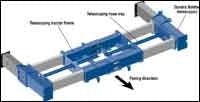

K-Five also recently traded a reasonably new, mainline Guntert & Zimmerman S1000 for one of G&Z's mid-sized S800 pavers. The telescoping frame and bolsters of the Quadra System allow width changes in less than a day—not as fast as a hydraulically variable machine, but the machine can pave 34 feet wide at a quality level equal to the big paver they traded.

"States want smoother riding surfaces because the vehicles on the road will bounce less. Less bouncing of the loads will mean longer pavement life. They want you right on the ride numbers," Gorski says. "We want all the jobs we can get in and around Chicago, and we want to win bonuses doing them."

Dowel-bar inserters are available for mid-sized machines that can be unloaded from a trailer, installed on the paver, removed, and loaded back on the trailer without ever needing a crane. Tracking speeds continue to increase, so concrete pavers move more quickly around project sites.

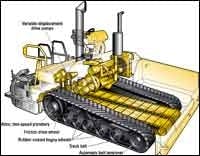

Mobility is a major driver of the convincing shift in asphalt pavers toward machines on rubber tracks. About half the pavers sold today are rubber-tracked machines. Much of the business is coming from steel-track users who need traction and stability for laying mat over sub-grade. Rubber track does the job as well as steel track, but has advantages in transport speed and maintenance-costs more like a machine sitting on tires.

Of course, there are some users of wheeled machines who have defected to get the stability and traction of rubber tracks. But those who are happy with tires—typically firms that lay mat over improved surfaces—tend to stay with tires because of lower ownership and operating cost. Blaw-Knox, Caterpillar, Cedarapids, Roadtec and Vögele all have one to three rubber-tracked options. Dynapac introduced a couple within the past year.

States' drive to improve pavement quality and durability has been forcing changes in asphalt pavers' material-handling systems. Hopper inserts have put more hot mix on the paver as state specifications choose material-transfer vehicles to encourage continuous paving (waiting for a truck interrupts mat quality). Increased load on the front of the frame has encouraged manufacturers to bolster the carrying capacity of front rollers on some wheeled pavers.

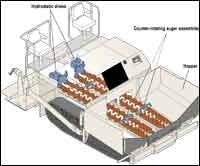

Another challenge to quality asphalt pavements is the segregation of large and small stone and hotter and cooler materials in handling. Material-transfer equipment serves a valuable purpose as it remixes the asphalt to keep a homogenous blend of aggregate and temperature all through the mat. Cedarapids replaces the slat and chain conveyors in its Remix pavers with a pair of twin-auger assemblies that draw mix from various areas of the hopper as they move material to the screed.

Focus on mat quality and protecting operators from harmful emissions in the paving process has piqued interest in alternatives to diesel-fired screed heaters. Electrically heated Carlson EZ Screeds are standard on Roadtec pavers and an option on Vögele America's line. Electric heat is an option on Cedarapids and Ingersoll-Rand's Blaw-Knox pavers, too.

Proponents of electric heat say it quickly delivers uniform heat from front to back and end to end of the screed, and even heat distribution generally reduces screed warping. Electric heat adds a generator to the paver, which is increasingly necessary to power lights for night paving. Most paver generators have extra capacity for running lights. Roadtec's for instance, makes available 4 kilowatts of 120-volt AC current.

Timers available on some fuel-fired heaters address some of the warping issues. They allow the heaters to burn for 15 minutes, and then automatically shut down. Since the asphalt typically keeps the screed at operating temperature after initial warm-up, many contractors would rather use diesel heaters and a timer rather than have to maintain an electrical heating system.

Both concrete and asphalt pavers are reaping pavement benefits and operator-comfort benefits from the shift to electronic engines that comply with EPA's Tier II emissions standards. Most machines sized for paving highways require electronically controlled engines, and many of them need a charge-air cooler to keep the exhaust clean.

The charge-air cooler gives the radiator fan one more component to cool, but engineers can use the computer monitoring the engine to cool more efficiently. Hydraulic fan drives are becoming popular on both black and white pavers because their speed can be varied infinitely within their operating range.

The hydraulic fan drive is controlled by the engine computer, which adjusts its speed according to information from the coolant-temperature sensor. The fan only spins fast enough to keep the temperature within an acceptable range. When they use an airfoil fan that moves air more quietly, you end up with a paver that easily satisfies ambient-noise limits, and a cooling system that improves the paver's overall fuel efficiency. And because the fan is no longer tied to the engine, the cooling package can be positioned so that the fan draws cleaner air from above the paver, through the radiator, and pressurizes the engine housing.

We're on to the second generation of flexible-width, mid-sized concrete pavers, and we're well beyond the first generations of the major asphalt-paver innovations. As manufacturers refine these machines, the crucial differences between them will no doubt lie in their ability to deliver ride-quality bonuses.

href="https://www.caterpillar.com" target="_blank">caterpillar.com

| Web Resources | ||

| Cedarapids cedarapids.com | CMI cmicorp.com | |

| Dynapac dynapac.com | Gomaco gomaco.com | |

| Guntert & Zimmerman guntert.com | IR Blaw-Knox blaw-knox.com | |

| LeeBoy leeboy.com | Roadtec roadtec.com | |

| Vögele America wirtgengroup.com | ||