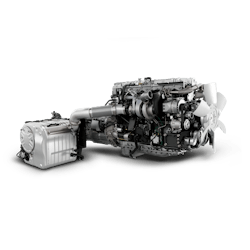

Navistar International has announced a new S13 Integrated Powertrain featuring a fuel-saving 12.7-liter diesel, whose exhaust is cleansed by an advanced aftertreatment system, and a 14-speed automated manual transmission. Its first application will be in aerodynamic highway tractors, where it will deliver up to 15 percent better fuel economy than did the current A26 diesel from 2017.

It will later be used in vocational trucks, executives said during an August 16 program at the Las Vegas Motor Speedway in Nevada.

Quietness and smoothness will please drivers, and a quick two laps around the infield track of the speedway seemed to verify that. This reporter drove daycab and sleeper-cab versions of the LT highway tractor. With the self-shifting T14, operation was effortless.

The powertrain takes its name from the S13 diesel, an inline 6-cylinder design with numerous advanced “clean-burn” features that allow a simplified exhaust-gas recirculation (EGR) system with no cooler. It has double overhead cams, a 23 to 1 compression ratio, relatively low-pressure oil pump, and a fixed geometry turbocharger—all to make the engine efficient, and simple and easy to service and repair, according to the company. Ruggedness will make the engine last for 1 million miles in highway service, said Michael Grahe, EVP for operations. Navistar will warrant some parts of the engine for as much as five years and 500,000 miles.

The T14 transmission has two creeper gears, and close ratios up to a direct-drive 13th gear and overdrive 14th gear. With a truck loaded, it will run mostly in 13th-direct, which is where the greatest fuel economy gains will be; 14th-overdrive will engage when loads are light or the truck is drifting downhill. The engine will come with a Jake-type compression brake that will make up to 469 retarding horsepower. The transmission’s warranty is as long as five years and 750,000 miles.

The aftertreatment system, called A/T, will use two-stage dosing of diesl exhaust fluid (DEF), the first just downstream of the turbo and the second in the system’s box-like container that will also house a diesel particulate filter (DPF). Clean burning of the fuel in the engine will help reduce particulate matter, and the DPF will be passively cleaned by constant heat. No fuel-induced active regenerations should be needed in highway service, though they can be actuated if necessary. And if a truck records 8.2 miles per gallon or more, no DPF servicing should be needed for 650,000 miles. Very little exhaust-gas recirculation is used so there’s no cooler.

The powertrain was collaboratively developed over five years by Navistar engineers and their counterparts at Scania in Sweden and Brazil who had begun two years earlier. It is the second product to come from the Navistar’s strategic alliance and merger with Traton.

The coming electric revolution means “this is the last internal combustion powertrain we will develop from the ground up,” said Grahe. Based on past experience, Navistar anticipates the engine will be used, with further refinement, for about 15 years, or into the late 2030s. Navistar’s aim is that half of all International trucks sold in 2030 will be zero-emission, meaning electric propulsion, and all will be zero emission by 2050.

The S13 diesel has undergone 4 million miles of field testing in extreme climates from Arizona to Alaska, and 400,000 hours of dynamometer testing—the most Navistar has ever done with a product. Scania has begun manufacturing the engine in Europe, where it’s called the Super 13, so it will have been in customer operations for two years before becoming available in North America in October 2023. Meantime, the powertrain will be placed with fleets over here for further testing and evaluation. A modular design allows the engine to meet the exhaust emissions limits of different countries relatively easily, as well as many trucking applications, Grahe said.

The S13 diesel for here will come in seven ratings, from 370 horsepower and 1,250 lb.-ft. of torque to 515 horsepower and 1,850 lb.-ft. The 400-horsepower, 1,850-lb.-ft. version will reach the best-case 15 percent fuel economy improvement, most of it from the engine. Starting next summer, the powertrain will be standard in upgraded LT and the RH regional tractors. No manual transmissions will be offered in the highway tractors because there’s a strong industry-wide trend toward automated gearboxes. Later, when the S13 goes into vocational trucks, they might or might not be offered with manual gearboxes.

“It will be the lightest 13-liter class powertrain in North America,” said David Hillman, director of integrated powertrain marketing. An S13 diesel alone weighs 2,284 pounds without fluids. Engine and transmission together weigh about 30 pounds less than the current A26 diesel with an Eaton Endurant automated manual transmission, which will be phased out as the S13 comes on line in mid-2023, and 650 pounds less than a 14.9-liter Cummins X15 with an Endurant HD autoshifter, which International will continue to offer. Navistar will produce the S13 diesel and T14 transmission at its expanded factory in Huntsville, Alabama.