If you manage equipment, no matter what your company title, you have metrics that you consider the most important. My top three are utilization, downtime and cost per hour. For the most part, I don't care how you define them or measure them; as long as you stay with whatever method you choose. Let's start with utilization.

Utilization (not availability):

Knowing utilization allows good management comparisons. For example, if you have a fleet of 20 similar-size wheel loaders, you can compare Brand A units to Brand B units of the same age. If Brand A utilization is significantly higher than Brand B utilization, then look into why. Is it used differently? Is it perceived by your field people as better designed for your work?

Andrew Agoos has spent more than 40 years in the equipment, service and maintenance side of heavy equipment. He has held senior management positions with Neff Rentals, Hubbard Construction Co., Austin Industries, and Caterpillar. He has strong opinions about equipment management: Some are based on facts; some are intuitive; some are anecdotal. He doesn't ask that you agree with him.

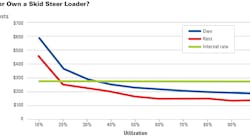

Utilization is also important because it tells me if I really need to own this machine. Utilization of on-road trucks is probably targeted to be around 95 percent. Most earthmoving equipment in southern states will be about 65 percent, and specialty machines such as soil stabilizers and pile hammers may be as low as 15 percent and still justify ownership.

Utilization is simply the time a machine works divided by the time it is required to work. Do not confuse utilization with availability. Availability is the time a machine is required and able to work divided by the time it is required to work. Availability is more complicated because it involves on-shift downtime, off-shift downtime, scheduled downtime (for example, PMs or track work), failures due to accidents or vandalism, standby time, and others. Your field people, the actual users, will probably want to know what standby time (some call this idle time) is recorded to account for weather, absent operators, or occasions when the machine is not needed.

Downtime (the inverse of uptime):

If you consistently measure downtime in the same manner, you can see differences when you change brands, oils, maintenance practices, extend life cycles, or any other significant variable. If you track on-shift downtime (let's call it Code Blue), you'll be able to spot problem machines or problem operations and do something about it during its life. And as equipment managers, that's what we are trying to do. My guess is that less than 10 percent of general contractors track downtime, and that's unfortunate.

Code Blue is what we all want to avoid. Planned downtime is not usually a problem. Daily fueling and maintenance should be planned events. On most of my jobs, we usually fuel and complete daily maintenance for critical machines before or after the work shift. For example, we can fuel, lube, and inspect the large excavators between 6 a.m. and 7 a.m. The fleet work begins at 7:00, and the articulated dump trucks, tractors, and compactors will be fueled and maintained throughout the day.

Cost per hour (for normal wear):

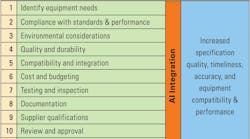

Cost-per-hour information allows you to compare Brand A to Brand B, compare operators (where assigned), compare Construction Division A to Division B, and better decide when to retire key fleet pieces.

This is the easiest metric to capture, but one of the most useful. I recommend you track and carefully trend normal wear operating costs excluding fuel and operators compensation. If you do include fuel, the data has to be accurate because the cost of fuel is so high. It's also better if you can separate and distinguish costs of undercarriage, tires, and ground engaging components because they are typically large buckets of costs.

Larger contractors tend to collect all three of these metrics. But no matter what your company size, if you plan to stay in business and make good, factual equipment decisions, you'll need some combination or all of these.