Anyone who appreciates simplicity of design and efficiency of operation has to like small two-stroke-cycle engines that power construction tools such as cut-off saws, rammers and breakers. Producing surprising power from their small displacements, these mighty little engines spin routinely at speeds of 4,500 to 6,000 rpm, produce plenty of torque for difficult jobs, operate reliably in the harshest conditions and often don't care whether they're running right side up, sideways or upside down.

To give an idea of the size and power range of these small, gasoline-powered, air-cooled engines (often called "two-cycle" or "two-stroke"), consider those used in the Partner saw line. They have displacements from 71 to 119 cubic centimeters (roughly 4.3 to 7.3 cubic inches) and horsepower ratings from 4.8 to 7.8. At the heart of the two-stroke's design, of course, is its ability to produce power (combust fuel) on every revolution of the crankshaft. The piston makes two strokes for every crankshaft revolution, hence the name. By comparison, the four-stroke-cycle ("four-cycle") engine makes two revolutions to produce the same relative power.

Because the two-stroke has no conventional valve train, it eliminates both the complexity and weight of the four-cycle's valves, cam, push rods, rocker arms, springs, seals and the like. Nor does the two-stroke have an oil sump in the crankcase, from which the four-cycle lubricates its pistons, bearings and valve train.

Instead, most construction-type, two-stroke engines rely on a small amount of oil mixed into the fuel for lubrication. Most often, the operator adds oil to the fuel. But, as alternatives, oil may be pumped from a small reservoir and injected into a fuel line leading to the carburetor, or may be injected directly into the intake manifold or crankcase. Wacker's WM 80 engine, used in certain rammer models, for example, has an oil-injection system with a pump driven from the rammer's crankgear. The pump meters oil into a fuel line, but stops pumping when the engine is at idle to prevent over-oiling. Electronic controls shut down the engine if the oil reservoir runs low, and the design also will allow shutdown after a pre-set idling interval.

The ratio of gasoline to oil varies by engine and manufacturer, but typically ranges from 16:1 (16 parts gas to one part oil), to 50:1. (Wacker's oil-injection system meters at a 120:1 ratio). Two-stroke oil is specially formulated to blend easily with gasoline and to remain in suspension. Strictly follow recommendations for oil type and ratio. Oils complying with NMMA (National Marine Manufacturers Association) TC-W3 specification are considered universal types for use in both air- and water-cooled two-strokes, but air-cooled models that run particularly hot may require a different specification.

The atomized fuel/air/oil mixture from the carburetor is drawn into the crankcase, where the heavier oil droplets collect on bearings and the cylinder wall. Bearings in small construction-type, two-stroke engines usually are high-quality, anti-friction types. Needle bearings typically are used on the wrist pin and connecting-rod journal, and large ball or needle bearings support the crankshaft.

The cylinders in construction-type engines typically have a cast-iron sleeve or are made of a super-hard alloy that allows installation of a new piston and rings without cylinder refinishing. The cylinder can be cast integrally with the crankcase, or are made as a separate, bolt-on component. Small two-strokes, in general, are highly serviceable, and repairing or rebuilding them hinges on what makes economic sense in your operation.

Today, in the interest of reliability and reduced maintenance, most two-strokes are running with "solid-state" ignition systems, and many are built with improved carburetor designs. Although two-strokes can run with various carburetor types (float and gravity, for instance), many use a diaphragm type. This carburetor employs a flexible-diaphragm fuel pump that is activated by the differential between atmospheric pressure and fluctuating pressure in the engine crankcase. The net result is that the engine can run perfectly in any attitude, even upside down. Some diaphragm-carburetor designs, such as Partner's SmartCarb, can compensate for dirty air filters by automatically adjusting fuel flow to keep the air-fuel ratio constant.

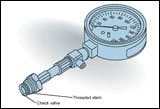

Two-stroke symptoms such as hard starting, starting when cold but not when hot, poor idle and rough running could indicate fuel or ignition problems. But, it's a good idea to first check compression. Test the engine cold, close the decompression valve and pull the starter until the gauge stops moving. If readings are below minimum values, check the piston, rings and cylinder before making other repairs. Best to use a threaded gauge that has a check valve.

Most manufacturers recommend cleaning carbon deposits from the exhaust port at intervals ranging from 75 to 300 hours. Observe cautions for positioning the piston during cleaning, and for purging carbon particles. Soak the muffler in cleaner and dry. Install a new gasket.

Because the spark plug is exposed to oil in the fuel, some manufacturers recommend cleaning and gapping the plug every week or at 25-hour intervals, and replacing it at one-month or 100-hour intervals. Keep cooling fins clean to avoid overheating, and check cylinder mounting bolts every week or at 25 hours.

Two-stroke engines use a variety of air-cleaning systems, which should be serviced with strict regard to the manufacturer's recommendations. Typically, systems are either neglected or over-serviced; both approaches are poor economy. If foam filters are to be oiled, use oil specially formulated for the purpose. Don't attempt to clean paper elements, which can be damaged in the process.

When fueling a two-stroke, exercise practical cautions: clean containers; clean fuel of correct octane; and recommended oil type mixed in the specified ratio. Over-oiling causes exhaust-port and muffler deposits, fouls the plug and increases smoke. A bad vent can cause engine shutdown. Replace in-tank and inline filters as recommended.

To enhance reliability, some manufacturers suggest periodically cleaning the starting mechanism and replacing the starting rope.

At the heart of two-stroke engine operation is the fluctuating pressure in its crankcase as the piston moves. As the piston rises in the cylinder, thus creating a larger open volume in the crankcase, a low pressure results. When the piston descends, thus decreasing open crankcase volume, a high pressure results.

The intake of the fuel/air/oil mixture occurs during the low-pressure phase. To allow the mixture to enter the crankcase, some two-stroke engines use a reed valve or poppet valve that is pushed open by atmospheric pressure, working through the carburetor, during the low-pressure phase. But as the piston descends and pressure in the crankcase rises, the valve snaps shut. Other engines may control mixture entry with a rotary valve (driven by the crankshaft) that alternately opens and closes an intake port in sync with the pressure cycle. Most small-displacement, construction-type engines, however, control intake with a "third port" or "piston port" that is opened and closed by the piston skirt in sync with pressure variations. Illustrated here, courtesy of Tecumseh Products, is a third-port-type engine.

Figure B: The piston reaches the top of its stroke, creating a low pressure in the crankcase. Atmospheric pressure then pushes the fuel/air/oil mixture through the carburetor and into the crankcase via the now-uncovered third port. The spark plug fires and the piston begins its power-stroke descent.

Figure C: As the piston descends, its skirt quickly closes the third port. The top of the piston begins to open the exhaust ports, allowing combustion gases to escape. The descending piston also is causing pressure to rise in the crankcase.

Figure D: When the piston reaches the bottom of its stroke, it uncovers the transfer ports. The high pressure in the crankcase forces the fuel/air/oil mixture through the transfer ports and into the combustion chamber. The turbulent, loop-shaped flow of the intake mixture helps scavenge remaining exhaust gases. (Some engines use a "deflector piston," with a specially shaped dome, to direct the flow of exhaust and intake gases.)