Cooled-EGR systems incorporate a number of sensors and actuators that are controlled and monitored by the engine's electronics, and any malfunctions show up as fault codes in the diagnostic log. On a routine basis, however, cooled-EGR systems are virtually maintenance free. But, that said, the day-to-day health of a cooled EGR system—and that of an engine running with such a system—depends closely on the health of related systems.

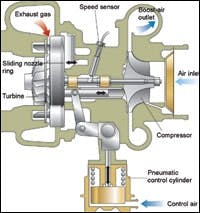

With the advent of cooled-EGR, turbochargers have become more complex. Most now have moving parts in the turbine section that allow continuous adjustment of exhaust-manifold and boost pressures to keep the combustion process efficient and legal. Turbocharger manufacturer Holset handles these adjustments with a variable-geometry turbine (VGT), which uses a sliding nozzle ring to vary the turbine-blade area upon which exhaust gases can act. Garrett, another major supplier, employs a variable-nozzle turbine (VNT), which uses a set of adjustable vanes, or nozzles, to direct flow into the turbocharger's turbine.

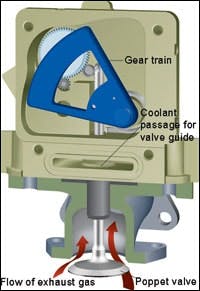

The moving parts of these turbochargers can be actuated electrically (with stepper motors) or pneumatically, typically using air from the truck's braking system. In either instance, the actuators are controlled by the engine's electronic control module (ECM). Likewise, the EGR valve, which regulates the volume of exhaust gas diverted to the cooler, may be electrically or pneumatically (or hydraulically) activated, again under the authority of the ECM.

For turbochargers and EGR valves using pneumatic-actuation systems, maintenance is twofold. First, if a small in-line filter is used in the air-actuation circuit, service it as directed by the engine manufacturer. Second, follow the vehicle maker's recommendations to the letter for maintaining the chassis air system. This includes faithfully servicing the desiccant cartridge in the air-dryer and regularly checking for moisture in the air tanks. More than a tablespoon of water in the tanks could mean it's time to replace the dryer cartridge.

Keep in mind, too, that an air compressor running hot (because of a faulty governor, a faulty air-dryer purge valve or braking-system leaks) can vaporize compressor oil and may foul pneumatic actuators.

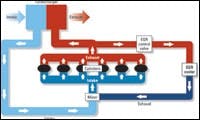

The cooler in a cooled-EGR system typically is made of a corrosion-resistant alloy, and its job is to reduce exhaust-gas temperature from around 1,100F to 300F. The cooler depends on a well-maintained engine-cooling system to do its job. This means, first of all, keeping the system full of coolant. Big trucks typically require frequent radiator top-offs, and paying attention to the coolant level becomes more critical with cooled-EGR engines. Be more conscientious, too, about checking for leaks in these higher-pressure systems, and be equally vigilant about checking belt tension and fan-drive operation.

Because the cooling system is working harder in a cooled-EGR engine, you'd be well advised, also, to keep a close watch on coolant condition. Fully formulated conventional antifreeze is standard factory fill for most big trucks, but long-life coolants with carboxylate- or bezoic-acid formulations are popular options. Whatever antifreeze you're using, check it regularly for freeze point, for correct color (has it been mixed with another type of antifreeze?) and for clarity (rusty?). And, remember, conventional antifreeze must be checked regularly for nitrite content to protect the engine's cylinder sleeves.

In a perfect world, antifreeze types would never be mixed in a truck's radiator. But they are, frequently, and two potential effects are worth noting. Some say that if a carboxylate-inhibited antifreeze (which includes most "long-life" products) is mixed with fully formulated conventional antifreeze, then the coolant becomes more acidic. This condition may cause silicates in the conventional to drop out. Some question if the resultant solids could deposit in the EGR cooler or in the coolant passages of "water-cooled" turbochargers. Also of potential concern is that mixing antifreeze types will dilute their respective inhibitor packages, to the point that not enough of either inhibitor technology remains to afford corrosion protection.

So the advice is easy, but the application difficult: Do your best to keep one type of antifreeze in your truck's cooling system.

As you may know, concerns about cooled-EGR engines running hotter and potentially dumping more acid and soot into the engine's lubricating oil prompted the development of a new heavy-duty oil, designated CI-4 by the American Petroleum Institute (API). By all accounts, the new oil is doing a good job, and many truck owners are tempted to use the same extended drain intervals established for the previous oil, CH-4.

While some in the industry say that's probably okay to do, others advise caution. The best advice is to follow the manufacturer's recommendations until a cautious oil-analysis program, involving both the engine manufacturer and oil supplier, yields convincing evidence that extended drain intervals are justified.

This Holset turbocharger uses a sliding nozzle ring to vary the flow of exhaust gases through the turbine section. A pneumatic cylinder, supplied with air from the truck's braking system, controls the ring's actuating mechanism. A speed sensor communicates with the engine's electronic control module, which determines when and how much the exhaust stream must be closed down to regulate exhaust-manifold and boost pressures.

Illustration: Holset/Cummins

The EGR valve, controlled by the engine's electronic control module, regulates the volume of exhaust gas diverted from the exhaust manifold and into the EGR cooler. This EGR valve used in the Cummins system employs a stepper motor and a gear train to open and close the poppet valve by precise amounts to regulate the volume of exhaust gas.

Illustration: Cummins

Illustration: Garrett