Just two years after LeTourneau introduced the first rubber-tired high-speed motor scraper in 1938, the Euclid Road Machinery Co. offered an alternative way of moving dirt at high speed over long distances.

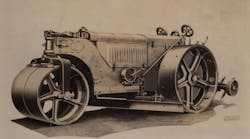

The Euclid BV loader ("BeltVeyor") scooped up material in relatively thin layers as a scraper, but instead of carrying the material inside itself, it loaded bottom-dumping wagons moving alongside by means of a conveyor. Once loaded into wagons drawn by four-wheel heavy-duty tractors, the material could be hauled more efficiently over longer distances than by employing motor scrapers. Utilizing digging and loading technology taken from earlier elevating graders, the BV loader was pulled by the largest crawler tractors available, such as the Caterpillar D8.

World War II hampered the progression of the BV loader beyond the experimental stage, but then the machine was exhibited at the 1948 Chicago Road Show, where it attracted much attention.

Categorized as a continuous excavator, the BV Loader could achieve high outputs if enough wagons were provided. As an example, when taking a 4-foot-wide cut 18 inches deep, it could load a Euclid 13-yard bottom-dump tractor/trailer unit in 30 to 85 seconds depending on the material.

The Euclid Loader enjoyed considerable success on the big dirt-moving jobs of the era, such as the Garrison Dam in North Dakota and the Ohio Turnpike where 19 units were reported used.

Although a great success in the early days of high-speed earthmoving, the Euclid BV Loader's popularity waned in the shadow of vastly improved motor scrapers entering the market. As a consequence, Euclid chose to discontinue manufacture in 1956. But the idea was not quite dead.

While under the ownership of the White Motor Corp. in 1969, Euclid took another shot at the belt-loader concept. The substantially larger "Super BV" boasted a 635-hp GM engine to drive the conveyor and four non-powered crawlers to support the machine. Although experiencing some success, including one machine that worked on the San Luis Dam in California, the Euclid loader concept once again lost ground to the more-flexible and efficient motor scraper, and only two of the Super BVs were built.

You can read more about the evolution of construction equipment in Keith Haddock's illustrated book "The Earthmover Encyclopedia" available in most bookstores. Also, consider a membership in the Historical Construction Equipment Association, www.hcea.net.