Savvy contractors have always had to be mindful of their owning and operating costs. This author remembers Peter Kiewit, whose company has been one of the world’s largest construction firms for decades, being quoted as saying that the key to success in the industry was to “know your costs.”

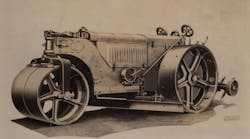

Let’s look at the cost of heavy earthmoving in the 1910s. The half-swing railroad shovel, for example, was the standard American excavator for dry-land digging of everything except solid rock—wherever the soil was firm enough to support the machine and the size of the job warranted its use. But the contractor could expect the machine to be actually loading haulers only about 60 percent of the time; the rest of the time was used breaking up material, moving, repairs, and waiting for haulers.

A new 2.5-cubic-yard shovel cost $12,000, and along with the three-man crew (engineer, boom operator, and fireman), the shovel also required a four-man pit crew, a watchman, and a team and driver to haul support supplies. Total manpower cost was $23.50 per 10-hour day. Fuel costs were typically around $12.00 per day—the machine usually burned three tons of coal at $4.00 per ton. Add in depreciation, 6 percent interest on the loan to buy the shovel, repairs, and miscellaneous expenses, and total owning and operating costs were $51.50 per day, or three cents per cubic yard at the normal production rate of 1,700 cubic yards per day.

Digging in stiff clay or shale would probably require two more laborers at $1.75 per man-day and reduce production to 1,000 cubic yards, raising cost per cubic yard to about $0.05. Blasting would require the two laborers plus four pitmen at the same pay, another ton of coal, and $1.50 worth of blasting supplies per day. Production would drop to 800 cubic yards, and cost per cubic yard would rise to $0.08.

Also in the 1910s, trucks came into widespread use for construction. In 1916, White Motor Co. offered the Good Roads Truck, a dump truck designed for road-improvement projects. It was named for the Good Roads Movement that started with the bicycling craze of the late 1800s and came to fruition with the advent of motor vehicles. White’s big selling point was the cost savings over horse-drawn equipment for road maintenance: The Good Roads Truck cost $250 to $400 a month to operate, said White, versus about $65 a month for a two-mule team and driver, but the truck could do the work of 15 such teams on average.

On one project, the hire of 20 mules and six men, plus feed for the mules, ran to $39.00 per day, while gasoline and oil for one truck, plus four men, cost $11.50 per day. On another, one truck maintained 55 miles of road per day with two graders (work that would have required four teams of eight mules) for less than the cost of feed for the mules. Montgomery County, Ala., reported that its six Good Roads Trucks enabled reworking the entire county road system after each rain with one truck and three graders for $0.45 to $1.26 per mile and reclaim gravel roads for $40.00 per mile.

Horses and mules also had to be rested for intervals often as long as their work periods. They were less productive in hot weather, had to be fed and watered whether they worked or not, and were subject to sickness and death. The truck, on the other hand, worked a full day and required fuel, oil, and maintenance only if it were working—no upkeep during downtime.

Teams were also limited in how far from their base of operations they could work, as transporting them significant distances was impractical. The truck solved this problem as well through its superior mobility, allowing roads far removed from the yard to be maintained.

The Historical Construction Equipment Association (HCEA) is a 501(c)3 nonprofit organization dedicated to preserving the history of the construction, dredging and surface mining equipment industries. With more than 4,000 members in 25 countries, activities include operation of National Construction Equipment Museum and archives in Bowling Green, Ohio; publication of a quarterly magazine, Equipment Echoes, from which this text is adapted, and hosting an annual working exhibition of restored construction equipment. Individual memberships are $32 within the U.S. and Canada, and $40 elsewhere. Information is available at www.hcea.net, 419.352.5616, or [email protected].