Dig and Load Faster With a Backhoe's Uniquely Combined Tools

Mastering the backhoe-loader is a big job because it is really two machines in one. A good operator can improve productivity by employing many of the same principles that make excavators and wheel loaders more efficient. But the best backhoe-loader operators know how to set up for many tasks to take full advantage of the rubber-tired machine's unique size and weight.

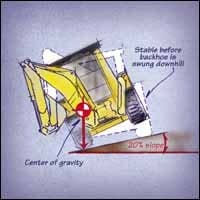

"Approximately one-third of the total weight of a TLB is in the two-ton backhoe assembly," says Gary Ober, professional operator and author of the book, Operating Techniques For the Tractor-Loader-Backhoe. "Because of its location high above the ground and far behind the wheelbase, the backhoe's weight transfers the entire machine's center of gravity upward and to the rear. The positioning of this weight when maneuvering around a jobsite is a concern for all operators. . ."

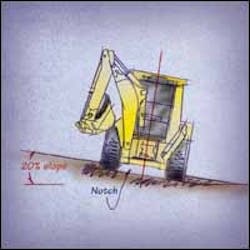

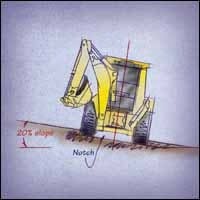

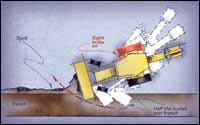

With a backhoe boom tip rising 12 feet into the air, slopes shift the machine's center of gravity downhill. The backhoe-loader's tendency to tip in these conditions is greater than that of machines with lower centers of gravity. Swinging two tons of backhoe downhill moves the center of gravity farther down the slope. If the bucket is full of dirt and the outriggers aren't deployed, the center of gravity may well extend beyond the tires. The machine will roll onto its side.

A loader full of dirt can also compromise stability on slopes. For example, driving downhill with a full bucket shifts weight from the rear tires. On a two-wheel-drive machine, it's important to keep as much weight and traction as possible on the rear because they're the only wheels with brakes.

Conversely, a machine may be stable driving uphill with a full bucket of dirt, but when the load is dumped into a truck, the loss of ballast can cause the machine to tip backward. Again, the concern is not that the machine might roll over, but that it will lose its ability to steer.

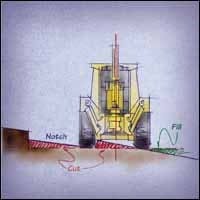

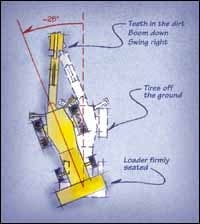

The machine is most stable for backhoe work when it is set up in what can be called the tripod position. Stabilizers are spread for the widest platform possible — not necessarily fully extended, but down far enough to raise the rear tires. The machine should be leveled for normal digging, but stabilizers can also tilt the machine to dig around obstacles in the excavation, or to slope the walls.

Each stabilizer is one leg of the tripod, and the loader bucket is the third. The loader should be in solid contact with the ground. If the front tires are carrying even part of the machine's weight, it will bounce slightly as the backhoe works. That bouncing will be transmitted into the operator and amplified through the controls.

Maximum digging force is achieved by combining the hydraulic power of the boom, dipper and bucket. The best operators use all three functions at once while maintaining the best bucket angle.

"When trenching, the goal is to shave layers of soil off, rather than gouge out chunks," says the narrator in a training videotape called Tips From the Pros: Backhoe-Loader from VISTA Start Smart Training. "Let the bucket teeth and cutting edge work for you. The teeth do the initial cutting by breaking the soil into pieces. The crumbling spoil begins to fill the bucket and the curling action holds the spoil in the bucket."

In normal digging conditions, start with the bucket floor at about a 45-degree angle to the ground. On harder surfaces, a flatter angle of attack will generate more cutting force.

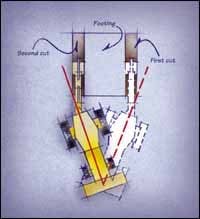

Concentrate on making the first cut exactly where the trench should be. It will guide all of the following passes, so make sure it's accurate. Digging a footing requires special precision because the walls of the excavation will be the form for the concrete pour.

"If it is dug too large, more concrete will be required; if it is dug too small, the reinforcing steel will not fit," says Ober. "Layout and digging techniques are extremely important because you only have one chance to get it right."

Pier-type footings require straight, plumb sides that are in exactly the right location. The excavation must first be precisely and clearly marked. Then the operator must align the backhoe so that long, straight strokes of the stick will align the excavation walls where the engineers want them.

Check the alignment by reaching out and touching the ground with the backhoe bucket's corner tooth next to the layout line. Boom up, stick in and touch the ground close to the machine. Do not swing the boom. The bucket should land as close to the layout line the second time as it did with the backhoe outstretched. If it doesn't, pivot the machine and check the alignment again until the boom is parallel to the layout.

Pivoting is a setup maneuver where the operator holds the stick vertically, digs the bucket teeth into the ground, and uses boom-down pressure to lift the rear end of the machine off the tires. Using the boom-swing cylinders, the operator can pivot the backhoe left or right on its loader bucket. Use the stabilizers as necessary to level the backhoe to dig plumb walls and a flat bottom.

After the guiding first cut is made, it's time to bale dirt. Each pass should be long and fairly flat, but the object is to move dirt as quickly and safely as possible until you're within six inches or a foot of the desired grade.

Cast the spoil as far from the trench as possible without wasted motion, placing spoil from the shallowest cuts furthest from the trench. OSHA requires a minimum of two feet between spoil pile and the edge of a trench. Unstable soils — whether it's because of sand or water or vibrations from nearby traffic — require more distance.

Clean up the area around the trench before final grading. "By sliding the bucket flat on the surface, the spoil will either be pushed toward the spoil pile or fall into the trench," says VISTA's Tips video narrator. "Also, now is the best time to remove any exposed rocks from the trench walls that may be a fall hazard."

A backhoe with extendible stick will dig more trench with fewer setups, but the benefits of additional reach come with limits.

"The machine isn't designed to work all the time in the extended position," says Dave Littlepage, product demonstrator/instructor at Caterpillar. "And don't forget to place the lockout pin in the stick when using hydraulic tools — the EStick is not designed to be fully extended while using things like hammers and plate tamps."

The Caterpillar Equipment Training Program for backhoe-loaders adds to the list of don'ts for extendible booms. "When the stick is extended, don't strike the ground with the bucket, fully extend the swing cylinder, backfill with the side of the bucket, use a large bucket, swing the load downhill, or reposition the machine (using the backhoe)."

Ober recommends digging most of the excavation — all except the finish grading — in two stages. Extend the stick and dig everything from the surface cut down to just above the finished grade. Then retract the stick and repeat the process closer to the machine. Fine grade the excavation in two stages as well.

For more details on excavator and wheel-loader productivity, which can be applied to backhoe and loader work, see the stories "Production Heroes Take the Textbook to the Trench" and "Take-Charge Loader Operators Fill Trucks Faster". Keep in mind, though, that there are many features unique to backhoe-loaders.

For example, when digging or loading from a stockpile, drive the bucket into the material and raise the loader arms to put down pressure on the front axle and get more traction from a four-wheel-drive unit. But in a two-wheel-drive machine, down pressure on the front axle unloads the rear drive wheels, reducing traction.

When working with the loader on the side of a hill, swing the backhoe uphill to stabilize the machine.

A four-way, or clamshell, bucket can unload sticky material better. Just open the jaw of the bucket and most materials will fall out without requiring a full dump cycle. This maneuver can also help backhoe-loaders reach trucks that are a little too tall for a full dump cycle.

| Training Resources | ||

| For more information about the range of operator training available from the sources in this story, contact the following companies: | Caterpillar Equipment Training Solutions , (800) 962-6628, www.cat.com | |

| Gary Ober Equipment Training Resources, www.equiptrain.com | VISTA Training , (800) 942-2886, www.vista-start-smart.com | |

About the Author

Larry Stewart

Larry Stewart was on the editorial staff from 1989 to 2010. His work won numerous editorial awards.